We intend in this article to do a brief review of the most common types of appeals shoring and shoring and to see what and how they are used. It is not our object to go into the details of the felling of each specific element (facades, walls, pillars, slabs, etc….), since that would provide for a complete manual and there are already many writings, nor to delve into the methodology of calculation of these elements, but only offer a review of the main systems used, both traditional and more current, showing their main differences, and those aspects that are common to all of them.

APPEALS AND SHORTS. WHAT ARE THEY?

Appeals and shoring are auxiliary constructions used to stop building movement, injury, or threat of ruin. They are also used for the execution of certain reforms or modifications in the structure of a building.

Although the words shoring and appeals are often used synonymously, the truth is that while shoring has the mission of transmitting loads through vertical elements (struts, right-foot, midget), shoring transmits the load in an inclined way (struts or braces).

In any case, we must bear in mind that both the shoring and appeals are temporary constructions, which are installed to consolidate a building affected by some type of structural exhaustion or because the works that are intended to be executed require a provisional structure that supports the loads while the works last.

To undertake these shoring works, a preliminary study must always be carried out of the causes that have produced the existing injuries in the building, in order to adopt the most appropriate solution for each case, always keeping in mind the variables of cost and time of permanence of the shoring.

Also Read the (TYPES OF SHORING)

CONSTRUCTION SYSTEMS

Traditionally, the shoring has been carried out using pieces of wood, which according to their position were designated in different ways (right-foot, brachial, coal, crutch, corbel, dwarf, etc….). They could be made with whole pieces or by adding several smaller pieces joined by flanges. The measurements of these pieces were variable, the most common being the use of boards about 20 cm wide and between 5 and 7 cm thick. The addition of several of these flanged parts was what formed the final section of the strut.

In this way, different constructive arrangements could be adopted depending on whether it was a question of lowering a slab, a beam, a pillar, a wall or a facade. In any case, the wooden pieces must be of good quality, and be properly braced.

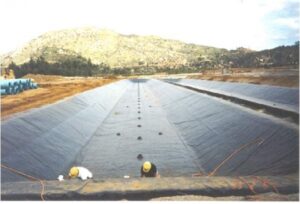

Although these wooden props are still in use, and are still used in certain situations, nowadays the normal thing is to go to metal elements. These elements can be laminated steel profiles, used in a similar way to wooden elements but with the characteristics and resistance of steel, or they can be height-adjustable metal props whose resistance is known and certified by their manufacturers, which They usually provide resistance tables for them depending on the height at which we adjust the prop. These metal props are used almost exclusively in the vertical shoring of floors and beams.

Another possibility of shoring is formed by prefabricated metal systems made up of modules of lightened metal beams (faveolated), but with great joint flexibility, which allows, by means of special pieces, to adopt any kind of shoring solution. In Spain it is known as SOLDIER SYSTEM, and as we say, its great flexibility allows it to be adapted to any type of shoring design.

COMMON ASPECTS

In any case, the process to be followed in a shoring must always be from bottom to top, with due precautions when loading the struts so as not to produce direct actions on the building.

In this regard, it must be taken into account that the ideal would be to be able to carry the loads of the lowered element to the ground, but this is not always possible. The most typical case consists of the shoring of a floor of an apartment building in which it is not possible to access the lower floor. In these cases, it is essential to estimate the bearing capacity of the existing slab in order to know its capacity to support the load of the upper slab to be lowered. Otherwise, felling would be unfeasible, and it would be necessary to look for other alternatives.

Attention must also be paid to the point of contact between the supports and the building, ensuring the correct transmission of loads from one to the other, and to the ground, arranging the necessary supports and sleepers. Once the shoring is arranged, it must be reviewed periodically, in order to verify that the pieces have not become misaligned and that they have fulfilled their function of stopping the unwanted movement of the building.