1: COATING USED IN CHANNELS LINING

-

INTRODUCTION CHANNEL LINING:

CHANNEL LINING is the main physical means for conducting water from its source to irrigation areas. In some areas, for climatic, topographic, accessibility reasons, or maintenance costs among others, other means are used such as pipes or tunnels, etc. However, for economic reasons, in practically all the projects the canal is always present, either in the conduction or in the distribution of the water. In the case of the study, we will limit ourselves to providing different types of coating in which we will be able to know which one to use; for the different problems that arise in the professional field.

-

CANALIZATION:

Channeling is understood to be the act or fact of channeling through artificial works the natural channel of a watercourse. The purposes of a canalization can be multiple to delimit the cause, protect the margins against erosion or floods, recover land.

-

COATING:

The lining and protection of the margins of the pipelines can represent up to 25% of the cost of implantation of these works, notably in the uses destined for navigation and drainage. For this reason, the adequate design of these elements must deserve careful analysis and attention, to combine the best technical performance with the lowest cost. However, it’s cost and duration depend on the quality of the coating and the proper management of surface waters.

-

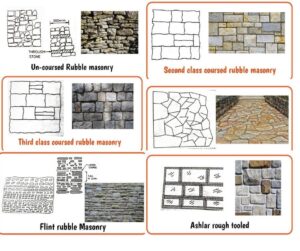

MASONRY CHANNEL LINING:

Masonry is an excellent channel lining. Masonry coatings (stone, brick, block, etc.) can be used when these materials are abundant and labor is inexpensive and recommended. Those made of stone can be built by joining with mortar or simply arranging it (zapateado).

-

CONCRETE CHANNEL LINING:

Reinforced concrete liners are used when the canal is constructed at sites where temperature changes are extreme and there are frequent fluctuations in flow rate. Reinforcing steel serves to prevent cracking of the concrete as a result of these temperature changes and to control cracks and thus seepage. The section of the reinforcing steel in the longitudinal direction is from 0.1 to 0.4% and in the transverse direction from 0.1 to 0.2%, it represents an important part of the total cost, and sometimes it is possible to eliminate it through the construction joints. Concrete lining, although it involves a high initial cost, in turn, presents multiple advantages, since it is very durable, maintenance costs are minimal and its capacity increases because the surface is relatively smooth.

-

MORTAR CHANNEL LINING:

Cement gun-based mortar liners are used in small channels, but the procedure leaves a rough surface that must be finished by hand if a first-class one is desired. They are also more prone to hydrostatic pressure failure. The thickness is not greater than 5cm on firm slopes. The cement is mixed with sand previously sifted through mesh No. 4 of 4.76 mm opening, in a ratio of 1: 3 to 1.4. Portland cement mortar applied by pneumatic means is used to line ditches and canals.

-

COATING WITH ASPHALT CONCRETE:

Asphalt concrete is a mixture of sand, gravel, cement, and asphalt, carried out at temperatures of 160 ° C or more, depending on the type of asphalt. Asphalt concrete-based coatings have some advantages due to their flexibility and resistance to erosion, although they fail due to weathering. The thicknesses vary from 6.5 to 10cm depending on the size of the canal. The asphalt is mixed with sand or with sand and gravel in a proportion of 6 to 11% by weight and then the fine material is added (70% smaller than the opening of the mesh No. 200).

-

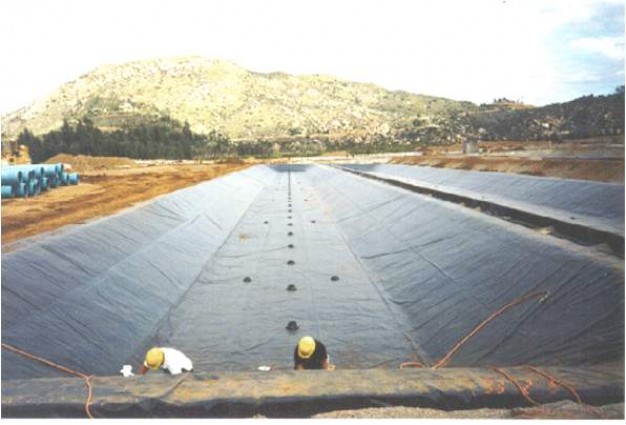

COVERING WITH RENO MATTRESSES:

Can act as margin protection and as partial or total coating of the bottom, when necessary, these mattresses can be used to favor the rapid recovery of vegetation, integrating the channeling into the environment. In the adduction channels, Reno mattresses act as protection for the waterproofing element (generally geomembranes placed between two non-woven geotextiles), minimizing, due to their weight, the effects of under pressure (photos A and B). low speed.

-

PERMANENT MANTLES:

Open channels on land are susceptible to eroding due to the drag force of the water flow that generates shear forces on their surface, causing material detachment, which leads to the loss of the section and the reduction of its hydraulic performance. The permanent TRM mantle provides immediate protection against erosion on the surface of channels on land in the absence of vegetation thanks to its high resistance against hydrodynamic forces present in the flow of water, it also supports the growth and establishment of vegetation and reinforces the mature vegetation, thereby maintaining the design section of the canal and its long-term good operation.

-

GAVIN COATING CHANNEL LINING:

The gabion covering is mattress-shaped, 20 or 30 centimeters thick. Its main applications are the lining of canal and river margins, protection of bridge abutments, foundation form platforms, and consolidation of slopes on roads and communication routes.

-

ADVANTAGES OFFERED BY COATING

in erosion prevention channels. impossibility of breakage. elimination of vegetation. channel capacity increase. decreased maintenance costs. reduction of irrigation costs. protection of public health. shortening of the trace by the largest eligible slopes. elimination of the effect of salinization of the lands. conditions that the channel coatings must fulfill.

- The most commonly used materials for channel lining are masonry lining. lining with concrete. coating with Mortar. coating with asphalt concrete. lining with reindeer mattresses lining with permanent mantles. cladding with gabions.

-

CONSTRUCTION PROCESS OF THE COATING OF A CHANNEL LINING

PROCESS: Implantable. Truss placement: Cladding. Truss extraction. Curing of the lined canal. Filling of expansion joints.

Filling expansion joints: filling section

-

SECTION WITH MINIMUM COST CHANNEL LINING:

Once the technical convenience of lining a channel has been decided, a very important aspect of its design is to choose the dimensions of the section so that the cost of the coating material is minimal. This cost depends on the type of material and the volume used; the latter is in turn a function of the thickness and perimeter covered in the section. When the cost of the material is the same as the template and slopes (same material and thickness) and only the wetted perimeter of the section is covered, the minimum cost is obtained with the optimal hydraulic section, but if the material, thickness, or unit cost are different in template and slopes, the problem becomes more complex.

- In this regard, however, the following considerations should be taken into account: In areas of uniform topography, as shown in the figure, if you have the freedom to adjust the slope of the channel so that it is approximately parallel to the terrain, and if the coverings of the bottom plate and the slopes are of identical characteristics (equal costs), the channel designed with the criterion of maximum hydraulic conduction will frequently be that of the maximum economy.

- On the other hand, in canals built on land with irregular topography, as shown in the figure, or when the altimetric conditions of the project set the starting A and discharge levels at B, then a section of less width at the base than the maximum hydraulic conduction will require less over-excavation; that the higher cost of the net flow section can be offset. Note also that the width on the surface is now less, and if the cost of the land is appreciable, this circumstance also tends to favor the narrower section, whose width, however, must allow efficient maintenance.

- We have seen that the trapezoidal section of absolute maximum conduction corresponds to a regular half-hexagon. However, the costs of placing reinforced concrete for slopes of 60 ° can be such that a section with steep slopes, for example, 1.5: 1, ultimately results in lower investment, although the perimeter and net flow section are higher. If the bottom slab of a lined canal has different characteristics and costs than the slopes or walls, then the identification of the section with the maximum economy is complicated. – Consider the case of the design of a channel in a uniform regime, as shown in the figure, with the following characteristics: Fixed bottom grade. Known wear and roughness. Rectangular section. Recommendation regarding the inclination of the slopes of the over-excavation

- First, the information regarding unit costs will be updated and the function that evaluates the total cost will be formulated: In which Ca… Cn is the various costs for the concepts already mentioned. Then, starting with the width be corresponding to the section of maximum hydraulic conduction, and by applying the Manning equation, the depths are obtained for widths smaller than be; thus, defining the flow section and therefore the set of total costs: C1, C2, C3, Cn. C = Ca + Cb +… + Cn

- With the help of the graph, for example, the width and, consequently, the most economical section can be precisely identified:

- Note, however, that the requirement of minimum width, for maintenance reasons, could rule out the least cost solution. Once the alternative that, in principle, arises as the most recommended has been identified, its behavior should be verified in the face of other limitations such as that referring to the speed limit values: minimum to avoid sedimentation and maximum to guarantee the integrity of the coating. or cost.

- Channel design Firstly, the channels must conduct the catchment flows from the construction site where they work to the loading or distribution site. Now, depending on their functions, the channels can be classified in; First order channel or mother channel this is traced with a minimum slope. Second-order or lateral channel, these come out from the mother channel and the flow that these have is distributed towards the sub-laterals, now the irrigation area that serves a lateral is known as an irrigation unit. Third-order channel. They are born from the lateral channels, which is why they are called sub-lateral channels, the irrigation area that serves a lateral is known as a rotation unit. We could say that several of these units is an irrigation unit and several of these forms an irrigation system or commonly called a mother or first-order canal. The design of channels has several elements such as the outline of channels for this it is necessary to collect aerial photographs, cultivation areas, hamlets, among others. Other elements are topographic and cadastral plans. If there is no topographic information, we proceed to raise the relief of the channel, how do we do this, recognizing the terrain, making a preliminary line, and finally making a final line.

- Now how can we recognize the terrain, then by going through the area and writing down the factors that influence the determination of a probable axis of the line? For the preliminary drawing with a photography brigade, we lift the area, we nail the stakes of the preliminary polygonal and then the survey with a theodolite, then the polygonal will be leveled and the cross-sections will be surveyed, these will be done according to criteria, if necessary. a terrain with high relief distortion, the section is made every 5 m, if the terrain does not show many variations and is uniform, the section is maximum every 20 m. With the data of the preliminary drawing, the final one is carried out taking into account the scale of the plan, which basically depends on the topography of the area and the precision that is desired. On the other hand, in the design of channels when making the forced change of direction this is replaced by a curve whose radius must be minimal since the curve will not be hydraulically more efficient, instead, it will be more expensive by giving it a greater length or further development.

- After defining the channel line, we must draw the longitudinal profile of the line, it is advisable to draw the profile on a transparent graph paper and make it green as this is more practical than the canon and allows millimeter lines are noticeable on copies. This as a whole is known as a channel overhang, it must take into account the catchment points if it is an irrigation channel and the confluence points if it is drainage. The slope of the bottom grade must be equal to the average natural slope of the land, if it is not possible, falls or waterfalls are projected.

- The final plan of the longitudinal profile of a canal must present mileage, soil type, location of the works of art, slope, etc. It is important to bear in mind that when the channel is of maximum hydraulic efficiency when for the same area and slope it conducts the highest flow, this condition refers to a minimum wet perimeter. A very important point is that the channel design has different factors, although the final design will be made considering the different possibilities and the result will always be a compromise solution because all the risks and disadvantages can never be eliminated, they will only ensure that the negative influence is the greatest possible and that the proposed technical solution is not inconvenient due to high costs.