Before starting to discuss the factors affecting concrete workability we should know about the workability of concrete, the Importance of workability in concrete and also we need to know about the relations between workability and strength of concrete. In this article we will discuss these all things step by step.

What is Concrete Workability?

Workability is a physical property of concrete that affects strength, durability, labor costs, and concrete finishing. It is said that when the concrete is easy to place and compact evenly; that is, there is no bleeding or segregation.

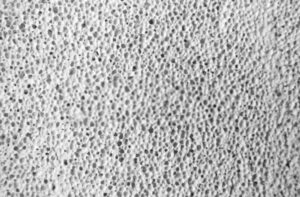

Unworkable concrete requires more work or effort to compact on-site; honeycombs can be seen even in precast concrete.

Workability is a property of raw concrete or fresh mixing of concrete. In short, machinability means ease of positioning, and applicable concrete refers to concrete that is easy to lay and compact without any insulation.

The workability of concrete is related to compaction and strength. The workability required for all types of concrete varies. For thinner or heavier hard-to-reach parts, instead of bulky concrete objects, higher is required. Therefore, we cannot define a standard mechanism for all castings. The degree of compression.

importance of Concrete Workability

The workability of concrete is very important in quality control standards and should not be ignored on concrete projects. Many factors affect.

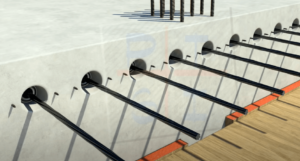

The workability of concrete is essential to allow concrete to be set and compressed into the formwork (in some cases with a concrete pump). The required processability (fluidity) depends on the mold’s size and shape and the pump’s use.

An increase in water content increases but reduces final resistance. Therefore, in some cases, specific fluidizing additives must be used to reduce the amount of water required to obtain the necessary concrete workability.

Types of Concrete Workability

When we say “types of workability”, we refer to concrete types with different . Therefore, there are three different types of workable concrete:

Un-workable concrete

Due to placing difficulties and issues such as segregation, their use in construction is never recommended. Because it cannot be mixed by hand, unusable cement is sometimes called hard cement.

Medium workability of concrete

For structures requiring light reinforcement, we use medium of concrete. It can work well in all types of concrete construction work. It is relatively easy to mix, transfer, and compact without negatively affecting separation and homogeneity.

High workability of Concrete

High workable concrete is used for structures or buildings reinforced with heavy steel that is difficult to compact. However, it is easier to transport, mix, position, and compress, but there is a high probability of separation and homogeneity loss.

Read Also: Concrete! Components and Production of Concrete

Relationship between strength and workability of concrete

The strength of concrete is our most important quality. It depends on density or compression rate, and compression depends on adequate concrete workability. Fresh concrete must be workable because it can be compacted with maximum intensity with a reasonable amount of work.

However, excessive will reduce compressive strength. Compressive strength of concrete decreases with increasing w / c ratio. An increase in the w / c ratio indicates an increase in workability. The concrete’s strength is inversely proportional. That’s why excessive of concrete should be avoided.

Factors Affecting on the workability

Water Content:

If the water content in the concrete is higher, it increases the workability of concrete. If the moisture content is below the required level, you will have difficulty managing the concrete and placing it in the correct position. Then water is added to the concrete according to the ratio of water to cement.

The relationship between the amount of water and the cement’s weight is called the ratio of water to cement. The strength and quality of concrete depend on this relationship. The amount of water is usually expressed in litres per bag of cement. If the cement bag’s water is 30 litres, then the water-cement ratio is 30/50 = 0.6.

The water to cement ratio should make the concrete have good workability, and the excess water affect the durability and strength of the concrete. The low cement water ratio makes concrete inoperable, while the excess water to cement ratio is subject to insulation. Keeping the quality and quantity the same as the composition, the ratio of water to cement determines the concrete’s strength.

Effect of Temperature on the workability of concrete

The temperature is the set value of compaction temperature, not the dosage temperature. However, the temperature harms all concrete properties (including workability).

When the total temperature of concrete increases, the fresh concrete decreases in the same proportion. In ordinary Portland cement, that is, cement without chemical additives, the effect of temperature on the workability of concrete is related to the cement’s hydration process.

The increase in temperature is a considerable loss of water due to evaporation, which speeds up the cement’s hydration process. Therefore, when the concrete first hardens, the concrete drops sharply.

Effect of aggregates on the workability of concrete

Size of Aggregate

If the aggregate size is small, this means that a larger surface, more water, and more cement paste is required. Therefore, a larger aggregate will provide greater for a certain amount of water and cement paste.

Shape of Aggregate

The concrete workability with round or cube aggregate is greater than that of flaky or angular aggregates. It can make very hard concrete, such as angular or flaky aggregate. Due to the circular size of the aggregates, the friction resistance between the aggregates is significantly reduced. Therefore, the aggregate should not have an angular or flaky shape as much as possible to facilitate concrete curing.

Grading of Aggregate

If the aggregates are graded well, the less void content will be and greater. Therefore, the total should be graded as much as possible.

Surface Texture of Aggregates

If the aggregate surface is smooth or glassy, it will result in less surface area and better. The friction resistance between smooth particles is reduced, which leads to increased.

Effect of time on workability of concrete

Time has the same effect on the concrete workability as the temperature of the concrete. Undoubtedly, as the water reaction progressed, the concrete matrix hardened over time. The impact of time is related to the fluidity of the concrete.

Fluidity refers to the amount of water available in the concrete used to moisten the cement compound due to bonding. With the passage of time and due to the water’s reaction, when part of the water is used by cement hydration, the fluidity decreases, and some of the absorbed aggregate and part of it is lost in the process evaporation.

It should be remembered that over time, the decrease in depends on factors such as cement properties (alkaline content and sulfate content), the moisture content in aggregates, and initial concrete workability.

Effect of Admixtures on the Concrete workability

The presence and properties of admixtures and additives significantly affect. Superplasticizers and plasticizers can improve the susceptibility of many wrinkles.

Please note that the concrete mixture’s initial collapse (also known as reference mixture breakdown) should be around 20-30 mm for improved collapse several times at the minimum dose.

An active air blocking agent on the surface can reduce the internal friction between the particles.

Air bubbles can be thought of as synthetic micro-assemblies with a very smooth surface. They also act as ball bearings that slide between particles and provide better .

Effect of Vibration

Vibration puts a positive impact on the workability in concrete. It is the most popular method of compacting concrete due to its high.

In the concrete laying process, different sizes of vibrators are immersed in fresh concrete, which causes the concrete form to liquefy, thus reducing the internal friction between cement and aggregates and facilitating the mixture’s transportation.

Effect of Mix Proportion

According to the ratio in the concrete mixture design, we refer to all components that have a negative or positive effect on the workability in concrete. The ratio of water to cement is very important for the scaling factor that affects of concrete.

Test for the workability

- Slump test

- Bee test

- Compaction factor test

From all of the three, the most common and useful is the slump test. It is a field test, and the other two, the bee test and stress factor, are lab tests. Then, the formwork will be removed immediately in the vertical direction, and the concrete’s failure was the collapse of the concrete.

The recommended collapse values for different concrete structures are as follows:

- Road construction – from 20 to 40 mm

- Channel coating: from 70 to 80 mm

- Mass concrete – 20 to 50 mm

- Concrete for walls, slabs, parapets, pillars – from 40 to 50 mm.

- Normal RCC work – from 80 to 150 mm

How to improve the Concrete workability

Site engineers are always looking for ways to improve concrete . Now that I fully understand all the factors that affect concrete workability, it is time to see how we can improve the of concrete.

To increase there are some ways like

- By increasing the water-to-cement ratio, can be improved.

- Increase the size of the assembly.

- Use smooth, round aggregates rather than irregular shapes.

- Increases mixing time.

- Increase the mixing temperature.

- Use saturated and non-porous aggregates.

- Excess liquefaction mixture

Read Also: Different Grades of concrete – Their Properties and Uses