Different grades of concrete relate to the strength of concrete. Required properties of concrete are directly involved in the choosing of the concrete grade for any member of the concrete structure.

What is the grade of concrete?

The minimum strength of concrete after 28 days of initial construction, its strength, and composition are used to define the grade of concrete. The units of the strength of concrete are in MPa. It is usually represented by the letter M, which represents the Mix design such as M15, represents the mix design of concrete having 15 MPa strength. The concrete mix design is also represented by their compressive strengths in Newton starting from 5 Newton, to higher values. In this case, C10 has 10 Newton strength, C20 has 20 Newton strength, and so on.

Key factors to choose the grade of concrete

The key factors upon which the grade of concrete depends are as follows:

- Compressive Strength

- Workability

- Durability

- Water Cement Ratio

- Nominal size of aggregates

- Grading of combined aggregates

- Control of Quality at site

Different types of grades

According to IS456: 2000, the grades of the concrete are shown by M5, M10, M20, etc. where M denotes the strength of concrete at 28 days when a concrete cube of 15×15×15 cm3.

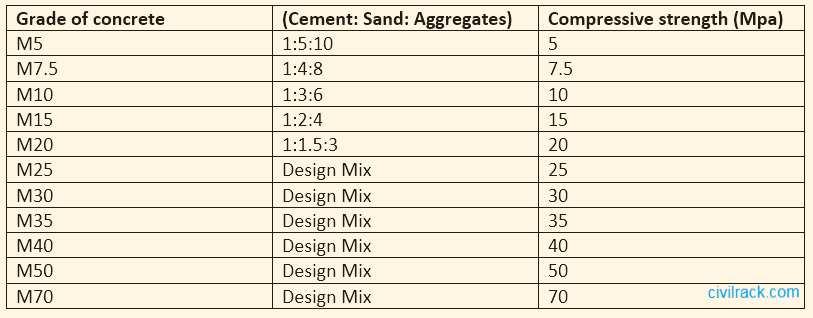

Concrete mix ratio for different grades, and different types of mix design

| Grade of concrete | (Cement: Sand: Aggregates) | Compressive strength (Mpa) |

| M5 | 1:5:10 | 5 |

| M7.5 | 1:4:8 | 7.5 |

| M10 | 1:3:6 | 10 |

| M15 | 1:2:4 | 15 |

| M20 | 1:1.5:3 | 20 |

| M25 | Design Mix | 25 |

| M30 | Design Mix | 30 |

| M35 | Design Mix | 35 |

| M40 | Design Mix | 40 |

| M50 | Design Mix | 50 |

| M70 | Design Mix | 70 |

Classification of Concrete Grades

The grades of concrete classify the concrete into four types:

- Lean Concrete

- Ordinary grade concrete

- Standard grade concrete

- High strength grade concrete

Lean Concrete

It is a type of concrete mix in which the liquid content is higher than the amount of cement present in the mix.

M5 Grade Concrete

M denotes the mix ratio and the 5 represents the compressive strengths of a standard cube on the 28th day with effective curing. The strength is represented in MPa. The mix ratio is 1:5:10 (1 Cement, 5 Sand, and 10 Aggregate).

it is typical used to provide the uniform surface area to concrete and it is in immediate contact to the foundation as it is used as PCC for the foundations. It is a lean mix type of concrete and its applications are in non-structural work. PCC is strong to bear compression but weak in tension loading. It is mostly used for non-structural members.

M7.5 Grade Concrete

The mix ratio of design is 1:4:8 which means that 1 portion of cement, 4 portions of sand and 8 portions of aggregates. It is also a low strength type of concrete and due to its low tension strength and high compressive strength, it is used in portions of the structure where the loading is mostly of compression type such as in case of foundation of the structure.

Ordinary Grade Concrete

M10 Grade Concrete

The mix ratio for this type of mix design in 1:3:6. It is used in the substructure portion of the concrete structures. It is mostly used as PCC also known as Plain Cement Concrete. M10 concrete typically used in leveling, of course, bedding for footing and concrete roads.

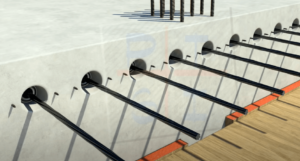

M20 Grade

The mix design ratio is 1:1.5:3. It is mostly used as RCC also known as Reinforced Cement Concrete. The main loading members of the structure which bear all types of bending loads are made with this type of concrete grade. As, concrete is very weak in tension so, in order to increase the tensile strength of the structural members, the steel reinforcement is added to the concrete to increase its strength. It is used in the making of beams, columns, and in slabs of the buildings. The concrete is resistant to mild exposure.

Standard Grades of Concrete

M25 Grade Concrete

It has mix design ratio of 1:1:2. It has same properties as the reinforced concrete but its compressive strength as compared to the M20 concrete as 25 Mpa, which significantly increases its uses in the structure to form the basic and essential loading members of the reinforced structure such as beams, columns and footings.

M30 grade concrete

The mix design ratio of this grade f concrete is 1:1:3 which denotes the 1 part cement, 1 part sand and 3 parts aggregate, which means that the strength applications f this type of grade are also higher as compared to lower grades of concrete. It is used in the making of beams, columns, and in slabs of the buildings. The concrete is resistant to mild exposure. It is made as per IS-10262-2009. .

M35 grade Concrete

This concrete has also its application the frame and masonry structures as the Reinforcement Cement Concrete. It is used in the making of beams, columns, and in slabs of the buildings. The concrete is resistant to mild exposure.

M40 Grade Concrete

As the strength of this grade is higher , its applications are in the essential structure where there are large amount of dead and live loads present .This concrete is also resistant to mild exposure. It is also used in RCC columns, pressurized beams, Runway concrete roads etc.

High strength Concrete Grades

M60 and M80 Grade Concrete

It is used as Reinforced Cement Concrete. These grades of concrete made for the structures where high strength concrete is usually required. It is used for high rise buildings, bridges, long-span bridges. Both of these perform exceptionally in highly aggressive environments. It has also many applications in spillways of dams, coastal constructions, and for constructing passage for dams.

Also Read : Different types of Concrete used in Construction