Concrete is a very important material in construction. Cast in situ and precast are two main methods of the concreting process. In this article, we will see which concrete method is better to cast in situ or precast concrete. Now let’s start with their introduction.

Cast in site Concrete

Concrete poured at the site is called cast in situ concrete. Cast in situ concrete also known as cast in place concrete. It is the conventional method of concreting this method is generally used in the world for most of the projects. In this method, formwork is made at the site and liquid concrete is poured in the formwork and then cured.

Precast Concrete

In precast concrete method concrete is made with reusable mould cured in a controlled environment, transported to site and fixed into place. Here a controlled environment is nothing but a precast plant.

Precast concrete members are cast and cured at a precast plant and then transported to site and only jointing will be done at the site.

I hope you got the idea that what is cast in situ concrete and Precast concrete?

Now we start our topic difference between the cast in situ concrete and precast concrete according to some factors.

Factors that affect to choose cast in Situ or precast concrete

These are some factors which are very important to choose a concreting process at the project.

- Time

- Quality

- Labor Cost

- Speed of construction

- Curing Conditions

- Weather Conditions

- Similar Components

- Form-Work (Shuttering and D-Shuttering)

- Concrete handling

- Number of joints

- Resistance to earthquake and Wind Pressure

- Contractor selection

- Material wastage

- Material Storage

- Quantity of materials

- On-Site test

- Plaster requirement

- Shifting cost

- Cranes

- Lack of knowledge

Time

In the case of precast concrete method elements like slabs beams, columns can be cast in advance does it saves time. Whereas,

in case of the cast in situ concrete method elements cannot be cast in advance that’s why this process takes more time to complete the project.

Quality

In the case of quality can be controlled and maintained easily because precast concrete is made in a factory. Hence, ideal conditions and exact measurements can be maintained throughout the process. Gives better quality than cast in situ method of concrete in terms of durability, stability and reliability. Water cement ratio can be properly adopted in precast concrete landing cast in situ concrete which can lead to better quality control.

whereas cast in situ concrete is costed at the site. Hence, quality is concerned with the workmanship.

Many times the cement slurry flows through the badly fitted formwork which can lead to poor quality concrete.

Labor cost

In the precast concrete method, less number of labor shall be required has only joining of members shall be done at the site and also less skilled laborers are required for this job. Hence labor costs can be saved.

For cast in situ method, more number of labourers shall be required as all he works like pouring mixing, shuttering D shuttering curing shall be done at the site and also for this world’s more skilled labour shall be required. And these all factors can increase the labour cost of the project.

Speed of Construction

The precast concrete method requires less time for onsite construction as compared to cast in situ concrete method. Because precast members are transported to site and can be directly lifted and placed on the desired position and there is no waiting for it to gain strength. It requires minimal propping embracing, hence, it speeds up the construction time and saves cost.

Whereas cast in situ concreting requires more time. Because Concrete requires minimum 20 days to achieve 99% strength of its total strength does after creating one element only after seven days a new element can be created, which is dependent on the previous one because concrete equals 65% strength of its total strength in seven days.

Curing Conditions

in the construction industry, curing takes major time in project completion. In precast, concrete method curing conditions can be controlled in a factory and high early strength can be achieved with the help of accelerated curing, the most commonly adopted curing techniques or steam curing at atmospheric pressure, warm water curing, boiling water curing and autoclaving.

Hence, there is no need of curing on site of the erection of members as members are already cured in the factory for desert is precast members can be installed immediately with no need of waiting for to gain strength and modularity like cast in place.

Therefore, it saves time and also reduces the cost of construction.

Whereas, in case of a cast in place concrete has limited curing is a difficult task and also it’s not worth hence, you will have to wait until the curing period gets completed. This increases the time of construction in the construction industry time is directly proportional to cost.

Weather Condition

In case of precast concrete weather condition does not affect costing work. If fabrication site for precast concrete can operate regardless of the weather precast concrete doesn’t shrink, distort or move and does not deteriorate with exposure to climatic change. Suppose, if it is raining and your precast slabs arrive on-site, then you can simply leave them into place.

Whereas in case of a cast in place concrete unexpected weather conditions can delay the casting book and if concreting is happening in cold weather then you can add cure time cost.

Similar Components

In the case of precast concrete construction, similar types of components are produced fast. Resulting in increased productivity and economic cost to thereby reducing the period of construction which can help to bring early returns of the investment. In precast construction. you can save the cost of concrete shuttering and de shuttering requires a fewer number of laborers.

Hence, you can save the cost of labourers to in precast construction please testing is done. Hence, it requires less reinforcement as compared to cost in situ concrete. As per research article published in the Journal of construction engineering (reasearchgate.net) on an average, the precast concrete slabs are 23.22% cheaper and precast columns are 21.4% cheaper than cast in place concrete construction, especially for large scale production. whereas in situ concrete is a cheaper form of construction for small structures.

Form-work (Shuttering and D-Shuttering)

The shuttering and de shuttering takes more time and space and hence increases the cost of construction, standardization and repetition. In the case of the precast method for repeated similar pieces like walls only higher as building, there is greater potential for standardization and repetition. The mould for the precast components can be used for a large number of repetitions, thereby reducing the cost of mould per unit.

Whereas, in case of cost in situ concrete the reputations of shuttering are very less as compared to precast. So, if limited standardization and repetition occur, then custom situ method will be more beneficial.

Read Also: Formwork (Shuttering)! Components and types of formwork

Precast Concrete concrete Handling

Precast concrete requires heavy machinery and cranes for handling which is lifting and installation of heavy elements.

In case of a cast in situ concrete method, the construction can be done without cranes.

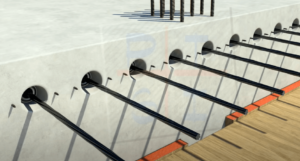

Number of joints

In the case of precast concrete, there are lots of choice instructional systems. In precast concrete construction, detail said the joint becomes very critical and needs careful attention.

Whereas in case of the cast in situ concrete, less number of joints will be present in the structural system and no serious attention is required for joints.

Resistance to earthquake and Wind Pressure

Precast concrete members are less resistant to earthquake and wind forces. hence, they are not recommended against seismic or wind loads.

whereas cast in situ concrete members are more resistant to earthquake and wind forces

Contractor selection

Precast concrete structure one needs a skilled and technical contractor.

whereas, costumes to a concrete structure can be built by local contractors.

Material wastage

Precast concrete construction wastage of materials is negligible as compared to cast in place concrete. Whereas in case of a cast in place concrete method the wastage is more real. Precast structural members can be reused extended and refitted internally because structures do not need to be demolished and can simply be renovated internally conserving resources reducing waste and landfill.

On the other hand, cast in situ concrete structures cannot be reused.

Material Storage

In case of precast method, there is no need for very less space is required for storage of materials and formal you can order this talk of precast members from the factory as and when required, so, it saves space.

Whereas, in the case of the cost in situ method, you have to keep his price result for storage of materials.

Quantity of materials

Compared to the cost in situ method precast method uses less cement, less water, less steel, and less labor as it is factory-made for the production of precast concrete, advanced mix designs, and better vibrations are used.

On the other hand, the cast in situ method needs more quantity of materials.

On-Site test

In the case of the precast concrete method strength test is carried out at the factory. Hence, an on-site strength test is not required.

On the other hand, concrete on-site strength tests are extremely important for ensuring that your building is safe. So, if you are going on-site casting, then this is this tape that cannot escape.

Plaster requirement

On precast walls due to plain surface less quantity of plaster shall be required as compared to cast in situ.

On the other hand, in the case of custom place concrete construction, it is a little difficult to get the plain finish on walls. Hence more quantity of plaster shall be required.

Until here we discuss both precast and cast in situ concrete. There is a lot of advantages of precast concrete, Here, may you think then why not use mostly precast concrete instead of the cast in situ concrete method? Now, Let’s find the reason behind this.

Shifting cost

To carry out precast concrete construction, transportation and shifting costs are more because of long distances from the factory very few precast plants are available.

Cranes

We cannot fix the precast concrete members without a crane. Cranes are very expensive to hire or purchase. This the 2nd reason to not use precast concrete more.

Lack of knowledge

Before going for the precast concrete method you need to check the following points type and size of the building. Generally, the precast concrete method is used for bigger-size projects, check the reputations of members, if the same type of floors is there, then you can go for precast technology otherwise it is not feasible.