Formwork is an important part of the concrete construction of different structures like Buildings, Bridges, and Dames. In this article, we will discuss the different components of formwork. Before starting the discussion on formwork components, we should know that,

- What is formwork?

- Requirements for a good form-work

- Cost/Economy of form-work

Now let’s start,

What is Formwork?

Formwork is a temporary mold or structure, which is made to provide support and shape to fresh concrete. Different materials are used to make the formwork, like wood, steel, plywood, and aluminum. And classifies with the material name, like wood formwork. Steel formwork, etc.

Formwork is also classified with the name of a structural member, like formwork for the column is known as column form-work. As the same, formwork for other structural members classifies by their name. Here are some examples, slab formwork, beam form-work, pier formwork, wall formwork, etc.

Formwork is very important in concrete structures. It consumes effort and time, it should be enough strong strength to bear all loads (a dead load of concrete, a Live load) that are applied to it.

Requirements for a good formwork

Here are some basic requirements for a good shuttering work

- It is very important that the formwork is well supported and strong enough to bear all loads applied to it.

- Form-work must be aligned and braced well from all sides to keep its original shape.

- It should be watertight to prevent the leakage of cement grout.

- It should construct in a proper way that at the removal stage concrete can be safe.

- The form-work material must be available locally, cheap, and can be used for more than one time.

- Try to keep lightweight as possible to prevent the extra load on supports. Especially in horizontal shuttering, lightweight formwork also can help to reduce labor costs or effort.

- It must be fixed in line and levels as per the drawing.

- Form-work material should not be damaged or rusted, which affects the quality of concrete finishing.

Cost/Economy of Form-work

Construction of form-work takes much effort and also consumes up to 20 to 25 percent of the cost of whole structure work. That’s why it is very important to keep it cost-effective parallel to its strength.

Here are some key points which can help reduce the cost of formwork.

- Try to reduce the variation in the building or structure design. It can help to reuse the shuttering again. And the way of reusing shuttering reduces its cost.

- Economical structure design can reduce the sections of structural members. Reduction of sections can help to fix less shuttering, in result cost can be reduced.

- Proper cutting of plywood and timber can also reduce the cost of shuttering.

- The use of the different engineered systems of form-work can reduce the labor cost and save time but as per material. They are costly, initially, they are not reducing the cost of shuttering. But in large projects with the saving time, can help to reduce the all-over project cost.

I hope you get the idea about form-work definition, requirements, and economy.

let’s start with the components of formwork

Accessories/ components of formwork

Here are the components of formwork,

- ties

- Hangers

- Anchors

- Props

- Spacer from Side

Ties

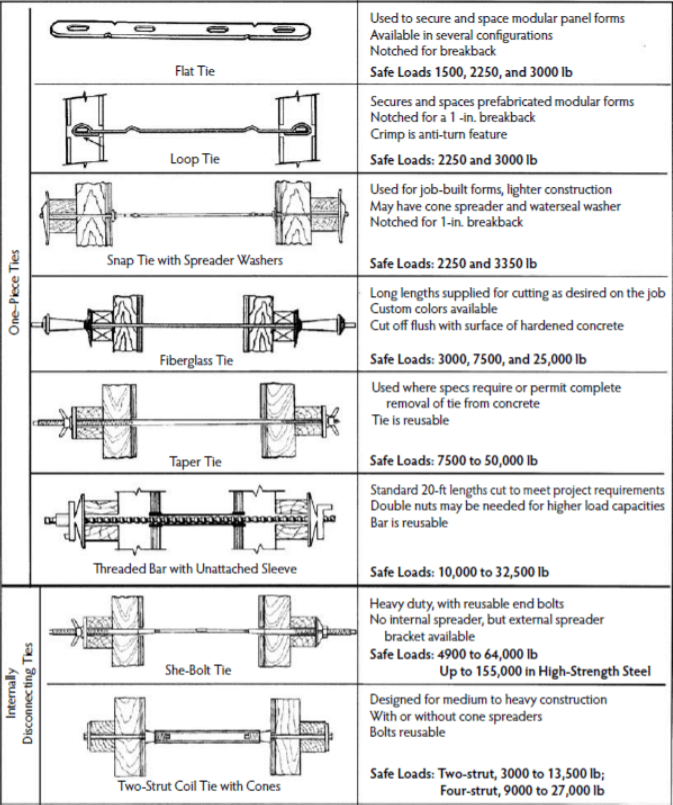

A form-work tie is a tensile unit used to connect opposite sides of the formwork. It provides a balanced connection or is used to resist the effective pressure of the fresh concrete.

Generally, it consists of an internal tensile member and an external holding device. related rods for use in table design.

Form ties are usually made of steel, although some fiber-reinforced plastic ties can also be used. There is a wide range of cable tie types and manufacturers’ rated tensile work capabilities.

Snap-on ties, ring ties, and flat ties are disposable ties. Usually, with a relatively low capacity (1500 to 3200 pounds), they are twisted and returned a specified distance from the concrete surface.

Coil ties, bolts, and bolts are examples of ties, some of which remain in the cast wall, and some can be reused.

The tapered cable tie (a tapered rod with threads on both ends) has been completely removed and reused. The tensile strength of heavy-duty cable ties can reach more than 60,000 pounds.

Some cable ties have a built-in function to separate the templates by a certain distance. This is especially true for disposable ties if this feature is ordered.

Another way to maintain the correct internal distance is to use a spreader to insert a strut (usually wood) into the formwork. When the concrete is poured to this height, it can be propped up with connected ropes or steel wires.

Anchors

The form anchor is a device used to fix the form to the pre-placed concrete with sufficient strength. The equipment is usually embedded in the concrete during placement. The actual bearing capacity of the anchor depends on,

- The shape and material of the anchor,

- The strength and type of the concrete embedded in the anchor,

- The contact area between the concrete and the anchor,

- The embedded depth and position in the member

Hangers

Form-work hanger is a device used to hang formwork load from structural steel, precast concrete, or other components.

Props

Vertical supports under the formwork are called props. it carries a load of shuttering and other loads including, structure load, material load, workman crafts load, etc.

In the traditional formwork system, it can be made of timber, but for heavy construction, it should be made of steel or aluminum.

Spacer from side

The side spacer is a device that maintains the required distance between the vertical shuttering and the steel bars.

Key Factors of safety for accessories

Here are some key points to using the accessories of formwork

- Rod-shaped or band-shaped ties are a common type of lightweight structure. These have supplementary devices for spreading the form and external holding means for engaging the form.

- The threaded internal disconnection type (also called a straight-through connection) is used in formwork for heavy construction. Usually, it is used in heavy foundations, bridge beams, powerhouses, locks, dams, and construction concrete. The removable part of all cable ties should be of a type that is easy to disassemble without damaging the concrete and leave the smallest possible hole for filling. Unless the contract document allows the tie to be left in place, the removable part of the tie should be removed. The minimum specification for shuttering connection must require that the supporting area of the external fixing device be large enough to prevent the formwork timber from being subjected to excessive stress.

- The form hanger should support the static load of the form, the weight of the concrete, and the construction and impact loads. The form-work hangers should be placed symmetrically on the supporting members and loaded through the appropriate concrete placement sequence to minimize the distortion or rotation of the hangers or supporting members.

- The form-work hanger should closely fit the flange or bearing surface of the supporting part in order to correctly transmit the applied load.

- Where the concrete surface is exposed and appearance is important, the hanger will not leave exposed metal on the surface. Otherwise, when the connecting hole is not punched, non-corrosive materials should be used to expose the connecting piece to the component.

Types of formwork

Formwork classifies into these types

- as per the material used

- as per structure member

- Engineered formwork systems

- as per usage

Type of form-work as per material used

- Timber formwork

- Steel formwork

- Plastic formwork

Type of Form-work as per Structure Member

- Column form-work

- Wall form-work

- Beam form-work

- Slab form-work

- Tunnel form-work

- Foundation form-work

Engineered Formwork System

- Climbing form-work

- Flexible form-work

Types of Formwork as per usage

- Reusable form-work

- Permanent or stay in placed form-work