Admixtures in concrete are substances added to the concrete mix to improve its properties.

The function of admixtures in concrete is to improve the physical properties of the concrete by adding substances such as air entraining agents, water reducing agents, and superplasticizers.

What are Admixtures in Concrete?

Every one of the items other than water aggregates (fine or coarse), fiber reinforcement and cement that are added to concrete are called admixtures.

As per RILEM (International Union of Testing and Research Laboratories for Materials and Structures).

Ordinary Portland cement mortar or glue (for admixture) are inorganic or natural substances which are introduced to typical parts of a mixture now not normally surpassing Five percent by using mass of concrete or cementations materials.

It is recommended to used admixtures in less sum. Assuming it is expected to add 2.0% of added substance and we add 2.05%, it will significantly increase workability of concrete. Admixtures are not utilized close by hand blending as hand blending isn’t accurate and uniform.

Advantages of Admixtures in Concrete

Admixtures communicate with hydrating concrete by physical and chemical activities. It is included in a little amount either in powder or fluid structure or on the other hand the mix is utilized when multiple property should be changed. It can also reduce the construction cost and economize the concrete construction

- Modify the property of concrete.

- Make concrete workable.

- Accelerate or retards the fundamental setting.

- Increases durability.

- Reduces segregation and bleeding

- Concrete produced by way of including admixture is pigmented, fungicide, germicides and insecticidal.

- To overcome emergencies during concreting working

What is the Function of Admixtures in Concrete?

Admixtures are substances added to the concrete mix to improve its properties.

The function of admixtures in concrete is to improve the physical properties of the concrete by adding substances such as air entraining agents, water reducing agents, and superplasticizers.

Types of Admixtures in Concrete

Following are the types of additives;

- Accelerators

- Air entering

- Water reducing

- Mineral admixtures.

- Superplasticizers.

- Retarders.

- Grouting admixture

- Underwater concrete admixture

- Shrinkage reducer admixture

Accelerators

These are admixture which decrease the setting time of concrete by accelerating the early strength achievement are called accelerators. It is not possible to used such admixture in prestressing concrete due to negative chamber development in prestress concrete. It is mostly used in colder regions. More it has greater possibility of corrosion

Example: Sulphates and alkali carbonates.

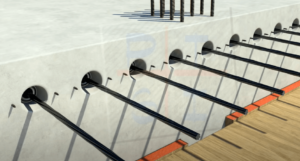

Air Entering

These are used to increase workability of concrete. These admixtures built small bubbles of air which enhance workability. It also enhances resistance to freeze-thaw (special effect). It also helps to reduce the effect of bleeding and segregation.

It causes reduction concrete strength due to presence of air voids. furthermore, its Reduces the cement content, cost, heat of hydration. Decrease the density of concrete, allow reduction in the content of water Reduces the alkali-aggregate reaction decrease the modulus of elasticity.

Example: Synthetic resins.

Water Reducer Admixtures in Concrete

Admixture which reduces the demand of water by increasing its fluidity are knows as water reducer. They are also called plasticizer. It helps in improving the workability of concrete.

These cannot be used by hand mixing, recommending used is in concrete batching plant under control environment. Extra usage of plasticizers increases cracking and causes strength reduction.

Working of Plasticizer

As a rule, these synthetic substances go about as dispersants for Portland ordinary Portland cement particles. By isolating and spreading out the cement particles, inside grating (i.e. friction) is decreased, furthermore, slump and workability of the substantial is expanded. Lowering w/cm (water cement ratio) is a key method for improving durability

The fundamental items comprising plasticizers are as follows:

• Anionic surfactants (surface strain reducers) like sulphonates hydrocarbons.

and their changes and lignosulphonates subsidiaries, salts of sulphonates hydrocarbons.

• Nonionic surfactants, for example, corrosive of hydroxylated carboxylic acids and their changes, polyglycol esters

In field fatty acid are used to reduce water by producing little bubbles that transport coarse aggregate.

Example: lime and Clay

Mineral Admixtures

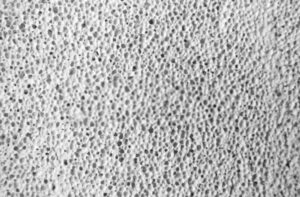

Today, most concrete combinations contain Secondary Cementitious Materials (SCMs) that make up a piece of cementitious part in concrete. These are for the most part the natural source or the result from different cycles (i.e., byproduct). They could possibly be additionally handled for use in concrete. Once in a while these materials are called pozzolans

Pozzolans are vast division of aluminouss and siliceous or siliceous materials which, in themselves, possess no cementitious or may also very little worth, which will finely divided form and with reaction with H2O (water) to react with calcium hydroxide chemically at room temperature to form compounds possessing cementitious properties. It tends to be utilized as a substitute for cement in concrete botching mixture

These are Finally divided siliceous materials. Which are combine in large amount. To enhance concrete ability. (Pozzolan activity also related to this)

Example: Pozzolans, Volcanic ash.

Super-Plasticizers

It has significantly greater ability to reduce the water content in concrete. That is why it is called super-plasticizers. It is also known as high range water reducer. It enhances workability of concrete It is mostly made from organic sulphonates.

It one the most expensive admixture to be used. To achieve the self-compaction property of concrete. Superplasticizer are to be used These cannot be used by hand mixing, recommending used is in concrete batching plant under control environment. Molecular structures for superplasticizer or high range water reducer (HRWRs)

Retarders

Aadmixtures that enhance the setting time and reduces rate at which water reacted with cement particles are called retarders. Widely used in hot and extreme region

Example: Sugar and starch.

Grouting Admixtures

It is a powder admixture which can utilized for make flawless cementitious grouts. It contains a water diminishing/plasticizing agent and a gas creating extension medium. It used for plastering with high pressure at walls to save time

It develops Higher Strength, greater fluidity and reduce permeability, bleeding

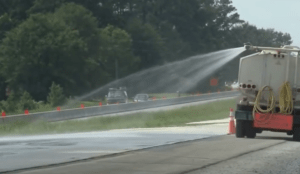

Underwater Concrete Admixture

Setting concrete submerged can be especially difficult task due to the potential for waste of concrete and fines from the blend, which can decrease the strength and respectability of the set-up concrete. In spite of the fact that situation methods, like tremies, have been utilized effectively for concrete to be submerged.

There are circumstances where improved cohesiveness of the substantial blend is required, requiring the utilization of an ant washout or thickness altering admixture viscosity modifying admixture (VMA). Another use of viscosity modifying admixture is to prevent segregation in high slump concrete.

The general advantage is a decrease in waste of time of concrete also, fines protection from weakening with water as the blend is put, and protection of the trustworthiness of the set-up concrete.

Shrinkage Reducing Admixture

The deficiency of dampness from concrete as it dries results in a volume reduction called drying shrinkage Drying shrinkage will in general be unfortunate when it prompts cracking (structural) because of either inner or outside restriction.

The greatness of drying shrinkage can be diminished by limiting the unit water content of a substantial blend, utilizing great quality totals, and utilizing the greater size coarse aggregates and content predictable with the specific application. Also, admixtures have been acquainted with assistance further decrease drying shrinkage.

These depend on natural materials like propylene glycol or related intensifies that decrease the surface pressure of water in the narrow pores of cement, accordingly diminishing the strain powers inside the substantial framework that lead to drying shrinkage

Read Also: What is Concrete Materials. How Many Concrete Type used

What is the Difference Between Hydraulic and Non-Hydraulic Cement Admixtures?

Admixtures are substances added to cement and concrete to improve the properties of the final product. There are two types of admixtures: hydraulic and non-hydraulic.

Non-hydraulic admixtures are not water soluble, meaning they do not need water to activate their properties. Non-hydraulic cement additives include plasticizers, air entraining agents, and superplasticizers.

Hydraulic cement additives require water in order to activate their properties. They include chemical admixtures such as air entraining agents, hydrated lime, and slag cement. .Hydraulic cement additives may also be mixed with materials to make them more fluid or to increase their volume. Some examples include chemicals such as fly ash, slag, and coal. Hydraulic cement is a highly viscous solution of lime (CaO) and water that hardens on contact with air or water to form a solid mass typically.

Admixes for Construction Performance

Admixes are a type of admixture that is added to the concrete in order to improve its performance. The admixes can be either liquid or powder and they are used in order to increase the strength and durability of the concrete.

Liquid admixtures, such as cement-based materials, are often used for their quick setting properties. They also have a higher water resistance and they make it easier to control the consistency of the concrete mixture.

Powder admixtures, such as gypsum, fly ash or recycled materials can be added to provide increased strength, durability and water resistance.

Water as an Admixture in Concrete

Water is a key ingredient in concrete, but it also has the potential to cause serious damage.

Water is an admixture in concrete, meaning that it is mixed with cement and aggregate to make the mixture more workable. It also helps the mixture to set and harden by reducing the surface tension of water in the mix.

But when water is added too much, it can cause serious damage because it reduces the strength of the concrete. If there’s too much water, then it can lead to cracks or even completely disintegrate and collapse as a result of not having enough cement.