Steel Pile Foundation

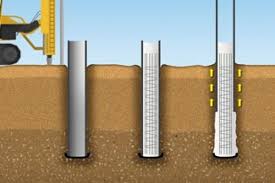

Throughout history, steel pile foundations have been the solution to foundation problems for offset steel structures in poorly competent soils that require displacing the foundation elements in deep layers with better mechanical behavior.

The evolution in construction procedures and the need to execute infrastructure works quickly have led to innovation in the type of material with which the piles are manufactured.

At first, steel piles were directly related to maritime and port works with tubular steel elements driven into the seabed.

Today the steel pile system in inland works with W or H sections is already a reality, Engineers who design with this foundation solution must take into account the same considerations as for any other type of foundation, estimating all the characteristics of the site and based on a detailed study of soil mechanics that provides enough geotechnical information to estimate the load-bearing capacity of the piles more closely to reality and to evaluate the most appropriate driving method to guarantee a good execution in the installation work of the piles for the foundations for steel structures.

Geotechnical Design

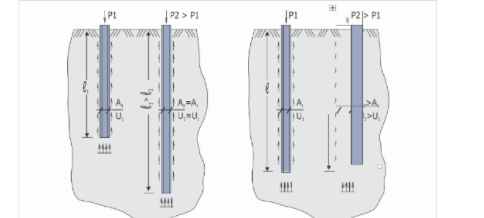

The admissible structural load, also called a characteristic load, is the maximum load that the pile will be able to resist since it corresponds to the structural resistance of the steel that makes up the pile. However, it is necessary to have a long enough pile to achieve this load from the point of view of the pile-ground contact. This procedure constitutes what is called “forecasting the load capacity”. Figure 1 shows two situations of piles of the same type, driven into the same ground. Case (a) corresponds to piles with the same perimeter “U” and the same tip area “A”, but with different lengths, in such a way that the longer pile will have a greater load capacity. Similarly, case (b) presents two piles with the same length, but with different perimeter “U” and tip area “A”. In this case, the pile with the largest perimeter and area will have a greater load capacity. Therefore, the project of a foundation consists of optimizing perimeters and tip areas according to the resistance characteristics of the soil and the limitations of the driving equipment.

It is evident that, in this optimization and whenever possible, piles and equipment should be used that allow them to be installed in such a length that the admissible structural load can be reached since that is the maximum load that the pile can withstand. But this is not always possible and, in general, the allowable pile load will be less than the structural load. For this reason, there are no tables of admissible loads of metallic piles (or of another type), for the design of a foundation for steel structures.

The corrosion resistance of steel piles.

Steel piles have been used around the world for over 120 years and their durability has exceeded all theoretical durability estimates, especially in highly aggressive or chemically contaminated soils. There are no reported cases in the international literature of structural failure caused by corrosion of steel piles.

The abundant literature available has indicated that natural soils are so deficient in oxygen that steel is not appreciably affected by corrosion, regardless of the type of soil and its properties.

Eurocode 1993-5: Design of Steel Structures – Part 5: Piling (1993) indicates that the thickness to be discounted from the pile is a function of the characteristics of the soil and the useful life of the project.

Corrosion rates of compacted soils are considered to be lower than those found in non-compacted soils, where the oxygen content is much higher.

It is important to highlight that Eurocode brings together the practical experience of many European countries, with different climate and soil conditions, which makes its use extremely wide and reliable.

Read more

Table 1: Loss of thickness due to corrosion for metallic piles in soils (mm), with or without water table, EN 1993-5

Useful life

5¹ years

25¹ years

50 years

75 years

100 years

Undisturbed natural soils

0.00

0.30

0.60

0.90

1.20

Contaminated Soils and Industrial Sites

0.15

0.75

1.50

2.25

3.00

Aggressive soils (swamps, mobs, marshes)

0.20

1.00

1.75

2.50

3.25

¹The 5 and 25-year values are based on measurements, the rest are extrapolated values

²The corrosion in compacted fillings is half that presented in the table

Driving steel piles with diesel hammers

These are the most used for driving foundation piles for steel structures. These are essentially made up of a ram, an anvil, and a fuel injection system.

Although diesel hammers are very competitive from the point of view of cost and maintenance, these types of hammers have a low driving efficiency ratio due to the loss of energy during the action of the mechanisms. The efficiency of the hammer is in proportion to the effective energy transmitted to the steel pile by the impact of the hammer, which, as we have already seen, can be reduced by the loss of travel distance and divided by the energy loss of the hammer. . Experimental tests during the driving process have shown that the efficiency of the diesel hammer rarely reaches 50% and its average efficiency usually ranges between 30 and 35%. See Figure.

Loading capacity

The estimation of the bearing capacity can be carried out in different ways, either through bearing capacity factors from shear strength parameters (classical soil mechanics) or empirical methods based on the results of field explorations. Due to the success in disseminating and practicing in the American continent of the Standard Penetration Test (SPT) and Electric Cone (CPT), the following analysis methods stand out.

The ultimate load capacity values shall be divided by a minimum safety factor of 3.0 for the resistance per tip and 2.0 for the resistance per shaft. In the case of using resistance factors, local regulations generally establish these multipliers in the range of 0.30 to 0.7

Driving steel piles with hydraulic hammers

The first hydraulic hammers appeared a decade ago in onshore works (oil platforms) where their good performance in driving elements submerged underwater guaranteed their success. In a few years, works with this driving method were developed in ports and offshore works.

The type of steel used (impact steel) and the existence of a single intermediate component that transmits the energy (the anvil) reduces energy losses and results in very high overall efficiency. The instrumentation during driving has shown that the efficiency is generally very acceptable hovering around 75%. In addition, these hammers are widely used because the hydraulic force is regulated very easily, and also the internal instrumentation that accompanies these mechanisms measures the kinetic energy of the hammer instantly. See figure.

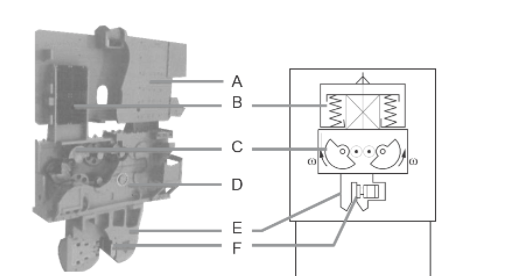

Driving of steel piles with Vibro-drivers

Vibro-hammer hammers were initially developed in Germany in the former Soviet Union (now Russia) around 1930-1931. Basically, its operation consists of rotating eccentric masses, in the opposite direction, as shown, schematically, in the figure.

Vibrating hammers

Vibratory hammers are generally classified according to the frequency imposed by the eccentric masses in:

Low frequency: those with a frequency lower than 20 Hz (1,200 rpm).

Normal frequency: they present frequencies between 20 Hz (1,200 rpm) and 33 Hz (2,000 rpm).

High frequency: they present frequencies above 35Hz (2,000 rpm).

In the image, we can see a hammer with a normal frequency.

Connections and splices

The splices or joints must be designed to resist all the stresses that may occur during the handling, driving, and use of the steel pile. Although the connections can be made with penetration butt welding, depending on the difficulties of the work, it is recommended to overlap welded joints, following the general recommendations contained in the manual of the American Institute of Steel Construction AISC for its acronym in English or the manual of the Mexican Institute of Steel Construction in its most recent versions.

The connection plates can be obtained from steel plates with resistance equivalent to the profiles, but for a matter of practicality, the connections are traditionally executed using a segment of the profile itself, cut as shown in the image, in the same way, They obtain the connecting plates for the skids and the web that will make up the joints of the pile on site.

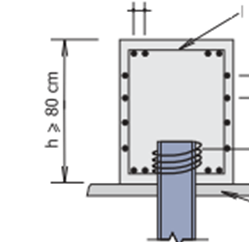

The diversity of projects and the particular conditions that each one presents, as a result of the mechanical properties of the soil and the magnitude of the loads that will be transmitted to the soil, causes the discharge on the pile to be of a very large magnitude, so it is advisable to distribute this load to more than one pile through concrete heads that will have the function of distributing the load to more than one pile.

Also, read (pile foundation)

The figure presents a typical example of a header with 1 pile embedded in concrete

The calculation of the reinforcing steel (stirrups) is not part of this work, as it depends on the loads applied by the columns to the header, the dimensions of the columns, the type of concrete, the stiffness of the header, etc.