Screen walls

Screen Walls: A wall or continuous screen is a type of containment element, whose main mission is to counteract the ground pressure and reduce its deformation; it is a common technique in civil engineering.

The main function of the screens is to contain and waterproof the walls of an excavation, also serving to collect the vertical loads that other structural elements can transmit to them.

Continuous screens are an effective solution to limit the movements of the ground, resulting from excavation, thus reducing the risk of damage to nearby buildings.

Frequent uses of screen walls:

Execution of basements in buildings

Execution of basements in buildings

Underground car parks

Protection of works threatened by water erosion.

Canalization works for the regularization of river channels against floods and erosion

Construction of underground lines, tunnels, and excavation of large excavations in urban centers

Large industrial works for the construction of wells, underground silos

Process

The first step in the construction of a continuous anchored screen is the execution of guide walls, reinforced concrete elements that guarantee its correct alignment. They serve as a guide for the excavation machine and help stabilize the walls of the excavation in its upper section. The walls are executed by excavating a trench in the line of the screen with a specific depth and width for each case, shuttering the two sides of the excavation while leaving space for the screen between them, and concreting.

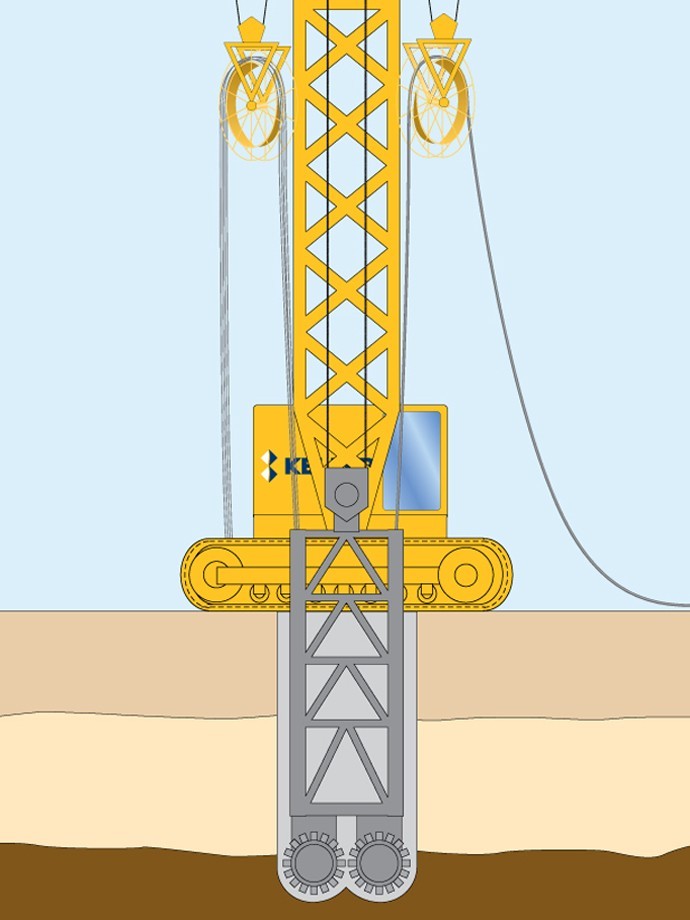

The excavation is carried out with special machinery selected according to the type and characteristics of the soil: for soft soils a clamshell bucket and hard soils a hydro frail.

The excavation is carried out in panels of different lengths, usually between 2.4 and 5 m until reaching the project depth. In case of detachment of the excavation walls, and to stabilize them, bentonite or polymer muds are used.

Once the project depth is reached, we proceed to: clean the bottom of the excavation by removing any loose elements; introduce the joint tubes, the reinforcement, and the tremie tube into the excavation; and the concreting of the panel, from the bottom up, through the tremie tube.

Keller Foundations executes continuous screens of different thicknesses from 450 to 1500 mm that can reach depths of up to 100m.

Also, read the (Shear Wall)

Advantage of screen walls:

Flexible structures capable of resisting the forces of the ground when deforming

Structural continuity element

Possibility of reaching great depths

It is not necessary to excavate or fill the back of the wall, so there is less decomposition of the treated land and damage to existing adjacent structures is avoided

Absence of vibrations and noise during the execution of the works compared to other techniques

Resistance and tightness against water seepage

Circular enclosures can be made

Possibility of execution both in the presence or not of the phreatic level

Quality guarantee

Keller Foundations has a fleet of equipment specialized in excavation and wall construction, capable of completing all types of sheeting and bearing capacity elements (bearing modules or LBE for its acronym in English).