Concrete is a common building material in the world. Where there is a vague idea of infrastructure, you can always find concrete there. However, not all concrete is the same. There are different types of concrete in the world for different purposes. One of the oldest concrete formulas in Rome is a mixture of volcanic ash and slaked lime. But centuries have passed since then. At that time, concrete has developed and become diversified.

Types of concrete

Generally, these different concrete types are used for construction and construction according to the type of building.

Plain Concrete

Plain concrete will have no reinforcement. The main ingredients are cement, aggregates, and water. The most used mix design is 1: 2: 4, which is a normal mix design.

The density of normal concrete ranges between 2200 and 2500 kg / m3. The compressive strength ranges between 200 and 500 kg / cm2. These types of concrete are mainly used in the construction of sidewalks and buildings, especially in areas that do not require high tensile strength. The durability of this type of concrete is highly satisfactory

Reinforced concrete

Reinforced concrete, in which steel is combined, allows the two materials to work together in resistance. Reinforcement bars, rods, or chain links absorb tensile and cutting stresses and sometimes compression stress in the concrete structure. Concrete is not easy to resist traction and pressure from wind, earthquakes, vibration, and other forces. Therefore, this is not suitable for most structural applications.

The compressive strength of concrete and the tensile strength of steel together enable reinforced concrete elements to withstand these stresses in a greater range. The invention of reinforced concrete in the nineteenth century revolutionized the construction industry. With the invention of reinforced concrete, cement became one of the most popular building materials globally.

Normal strength concrete

Normal strength concrete is similar to plain concrete as the same ingredients are used in its preparation. The initial setting time is about 30 to 90 minutes, depending on the properties of the cement used and the site’s weather conditions. The strength of this type of concrete ranges from 10 MPa to 40 MPa.

High Strength Concrete

The compressive strength of high-strength concrete is above 40 MPa (5800 psi). These concretes are made with low water to cement (W / C) ratio of 0.35 or less.

Silica fumes are usually added to prevent the formation of free calcium hydroxide crystals in the cement matrix, which reduces the strength of the overall cement bond. The low water to cement ratio and the use of silica fume reduce the concrete mixture’s workability, which is especially likely to become a problem in high strength concrete applications where rich tendons can be used.

Superplasticizers are usually added to the high-strength mixture to compensate for the low processability. For high-strength mixtures, aggregates must be carefully selected. Weaker aggregates may not be strong enough to withstand the load applied to the concrete.

Rapid Strength Concrete

Rapid strength concrete (RSC) is concrete that is rapidly gaining strength. Concrete resistance over 3000 psi can be reached in under two hours. The standard specification provides two options for the rapid processing of RSC hydraulic concreting. The first is the use of Portland cement of the third type, and the strength can be improved by using chemical additives.

The second option is to use other hydraulic cement with chemical properties to rapidly increase resistance, such as modified high alumina cement (MHAC) or calcium cleaved cement (CSA).

Key points to consider for Rapid Strength concrete

- When the project is expected to require a pressure resistance of 3000 psi or higher within 24 hours or less, RSC is permitted.

- The designer shall provide the required strength and 28 days’ strength when broken or broken. These may vary by design application.

- The water to cement ratio in MHAC and RSC of Portland cement is usually 0.3. Based on this, the 28-day strength is estimated to be 10,000 pounds per square inch. CSA cement-based RSC resistance curve is accelerated, but the maximum resistance is similar to conventional Portland cement concrete. If the higher final compressive strength of concrete is a problem for the design, then other special arrangements are required to reduce the strength to less than 28 days.

- The improved strength can also produce a higher processing temperature. When the minimum size exceeds 2 feet, the specifications of bulk concrete shall be observed. Note that this does not necessarily mean that cooling tubes will be required. The contractor will have to perform thermal analysis and determine which measures should be used to prevent maximum temperatures exceeding 160 ° F and prevent cracks from thermal differences during hardening and hardening.

High-Performance Concrete

High-performance concrete (HPC) is more durable than conventional concrete and more resistant when necessary. HPC mixture is the same materials as a conventional concrete mix. The proportions are still designed to provide the strength and durability required by the project’s construction and environmental requirements.

High-strength concrete refers to a specific compressive strength of 8,000 pounds / square inch (55 MPa) or higher. A value of 8,000 psi (55 MPa) is chosen because it represents a specific resistance level, which requires special attention in the production and testing of concrete, and may require special structural design requirements.

Ultra-High Performance Concrete

Ultra high-performance concrete is a new type of concrete developed by organizations interested in protecting the infrastructure. UHPC has the advantage of being a composite cementitious material reinforced with steel fiber, its compressive strength is greater than 150 MPa, and the highest of it may be greater than 250 MPa.

UHPC is also distinguished by the composition of the component materials: fine-grained sand, fumigated silica, fine steel fibers, and a special high-strength Portland cement mixture. Note that there is no large grouping. Current production types (Ductal, Taktl, etc.) differ from regular concrete in terms of compression, as it hardens to deform and then suddenly experiences brittle failure.

To know more about UPHC you can read research about UPHC here

Micro Reinforced ultra-high performance concrete

These types of concrete are the next generation of UHPC. Plus the high compressive strength, toughness, and abrasion resistance of UHPC. Fractional reinforced UHPC has excellent ductility, energy absorption, and resistance to chemicals, water, and temperature.

UHPC 3D multi-layer continuous small steel mesh exceeds in durability, ductility, and resistance. The performance of cut and dispersed UHPC fibers is relatively unpredictable. Optimized UHPC is precisely used for explosions, ballistic and seismic buildings, structures, interlocking buildings, and complex exterior walls.

Light Weight Concrete

Lightweight concrete is a mixture of lightweight coarse aggregates (such as shale, clay, or slate), giving it a characteristic low density. Lightweight structural concrete has a field density of 90 to 115 pounds per cubic foot, while regular concrete has 140 to 150 pounds per cubic foot. It makes lightweight concrete an ideal choice for modern structures that require the smallest foundation cross-section.

It is being used increasingly to build neat foundations and has become an effective alternative to regular concrete. However, using lightweight concrete can achieve an excellent compressive strength of 7000 to 10,000 psi. However, this will damage the mixture’s density, as it requires more pozzolan and water additives to be added to the concrete.

High-density Concrete

The density of these types of concrete ranges from 3360 kg / m3 to 3840 kg / m3, while regular concrete density is about 2,400 kg / m3.

Therefore, the density of high-density concrete is about 50% higher than that of conventional concrete. However, using iron as fine aggregates and coarse aggregates can produce concrete with a density of up to 5200 kg / m3.

With the advent of nuclear power, concrete technicians are in great demand in the market. Therefore, all units that generate nuclear energy, such as nuclear reactors, particle accelerators, industrial radiography, radiotherapy units, and gamma rays, require nuclear protective materials to protect operators from biological hazards such as radiation.

Regular and high-density concrete is efficient and economical to build permanent shields from radiation.

Self-Compacting Concrete

Self-consolidating concrete is concrete with low stress, high deformability, good separation resistance (preventing separation of particles in the mixture), and medium viscosity (required).

In daily use, SCC is an extremely fluid mixture with the following unique practical properties: It is very easy to flow in and around the mold, it can pass through obstacles and corners (“passage capacity”), very close to self-leveling (although it is not an automatic leveling), There is no need for vibration or pressure after casting, and the shape and texture of the mold surface (or shape) is very carefully traced after setting.

Therefore, pouring these types of concrete is also less labor-intensive than standard concrete mixes. Once poured, concrete is generally similar to standard concrete in time setting, hardening (increased strength), and strength. SCC does not use a high percentage of water to become liquid SCC contains less water than regular concrete.

Read Also: Different Grades of concrete – Their Properties and Uses

Ready-mix concrete

Ready-mix concrete is mixed in a central mixing plant and transported to the construction site, and is ready for use. When using precast concrete, attention must be paid to the time required for transportation because the mixture may harden if concrete reached the site late.

Ready-mix concrete is used in special cases, such as when large concrete quantities require construction joints.

Asphalt Concrete

Asphalt concrete is a composite material commonly used on road surfaces, parking lots, airports, and the core of dams. It consists of mineral aggregate bonded to asphalt, stacked in layers, and pressed

Stamped Concrete

Stamped concrete is usually called molded concrete or sealed concrete, using rubber seals with a “real stone” mold design to seal the concrete to make it resemble natural bricks, slates, gravel, tiles even chipboard. A cast concrete form can be used as a covering layer to cover an existing concrete slab or stamped into freshly cast concrete before hardening.

Polymer Concrete

These types of concrete are composite materials in which aggregates are bonded with a polymer binder in a matrix. Although Portland cement can be used as a compound or filler, these compounds do not contain a water-containing cement phase.

Polymer concrete compounds have a unique set of properties depending on the formula. It includes rapid curing at ambient temperatures from -18 to +40 ° C (0 to 104 ° F); High tensile and flexural strength and compressive strength; Good adhesion to most surfaces; And freezing and thawing cycles in comparison.

It has good long-term durability; Low permeability to water and strong solutions, Good chemical resistance.

Air-entrained Concrete

It is a simple form of concrete that contains small bubbles, ranging in diameter from a few thousandths of an inch to a few hundreds of hundreds of an inch, and typically accounts for 4% to 7% of the total volume of concrete.

The cavity created by the air bubbles expands as the water freezes, reducing the internal pressure of the concrete. It is produced by introducing an air-entrained agent while mixing concrete or using Portland cement to trap air.

Prestressed Concrete

Prestressed concrete is a form of concrete in which the concrete is initially compressed before applying an external load to counteract the stress produced by the external load in the manner desired during use. This initial stress is introduced by wires or high-strength alloy steel (called “tendons”) located in the concrete section.

Precast Concrete

Precast concrete is a form of concrete prepared, laid, and cured on-site with reusable molds in a controlled factory environment. This type of concrete is commonly used for structural components such as; Wall panels, beams, columns, floors, stairs, pipes, tunnels, etc.

Steel frames can provide an alternative to precast structural components, but precast concrete can be cheaper and sometimes more practical. Many buildings now combine these two building technologies, sometimes combining steel structure, on-site concrete, and precast concrete elements.

Glass Concrete

This modern concrete uses recycled glass as aggregate to increase the aesthetic of the structure. In addition to being resistant, this concrete also has a thermal insulation effect.

Vacuum Concrete

This type of concrete contains a high water content when mixed to improve workability, making it workable, and placed in complex molds or large steel bars.

The vacuum studies concrete that uses steam to create a vacuum inside the mixer to release air bubbles inside the concrete. Reducing the final water-cement ratio of concrete before hardening to check its strength and other properties.

When the steam condenses in the water, it creates low pressure on the concrete, which draws air out of the concrete. Since there is less air in the mixture, this will make the concrete stronger.

Shotcrete Concrete

This type of concrete is a mixture of aggregates and Portland cement. It is delivered by compressed air to the spray gun nozzle, and water is added to the nozzle. Then the wet mixture is sprayed in place and can be sculpted or smoothed almost instantly. For structural purposes, poured concrete is usually applied to steel bar structures and steel mesh.

Since it can take on any shape, it is easy to stain. It can be carved after construction, so drop concrete can be used for all kinds of fancy concrete structures, including artificial rock walls, zoo enclosures, canopy roofs, heat-resistant linings, swimming pools, and dams. It is sometimes used in tunnels to connect tunnel walls to prevent leakage and breakage

Pumped Concrete

Pumped concrete is used in tall buildings and places where it is not easy to transport concrete except for pumps.

It is easy to transport enough. Fine materials are used to enhance rendering. The thinner the material, the easier it is to empty it. The pumps used for transportation are made of rigid or flexible materials, and the concrete can easily be vacuumed.

Fiber Reinforced Concrete

Fiber-reinforced concrete (FRC) consists mainly of hydraulic cement, aggregate and separate reinforcing fibers. Fibers suitable for reinforced concrete are made of steel, glass, and organic polymers (synthetic fibers).

Asbestos fibers and natural plant fibers (such as sisal and jute) are also used for reinforcement. The concrete base can be a mortar, a mixture that is usually mixed in proportions, or a mixture specially prepared for a specific application. One of the most significant benefits of using fiber-reinforced materials is the best long-term maintenance of a structure or product if the design is correct.

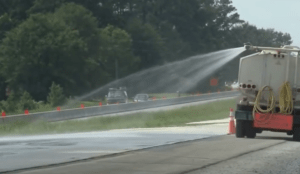

Roller Compacted Concrete

Roller compacted concrete (RCC) is a special concrete mixture whose composition is mainly similar to conventional concrete but different. More and more Portland cement is being used instead of fly ash.

The partial replacement of fly ash with Portland cement is an important aspect of RCC dam construction because the heat generated by the wetting of fly ash is much less than the heat generated by moistening Portland cement. It reduces the heat load on the dam and reduces the risk of thermal cracking. RCC is a mixture of cement/fly ash, water, sand, and common additives, but with a much lower water content. The resulting mixture is much drier and does not crumble. The RCC site is similar to the floor. The materials are transported by trucks with tipper trucks or conveyor belts, distributed by specially modified small bulldozers or asphalt pavers, and then pressed by the vibrating rollers.

Fly ash Concrete

The concrete that uses fly ash is called fly ash concrete. Fly ash is obtained from coal. Fly ash can replace fine aggregate or cement or partially replace both. According to reports, up to 30% are fine aggregate replacements and 20% cement substitutes.

Fly ash improves the workability of fresh concrete and improves the durability and strength of the hardened concrete. The particles size of fly ash must be finer than the particles of concrete

Silica Fume Concrete

Silica fume is a high pozzolanic substance that can improve the mechanical properties and strength of concrete. It can be added directly to concrete as a single ingredient or added to the concrete as a mixture of Portland cement and silica fumes.

Prepacked concrete

Generally, concrete is prepared by mixing different ingredients types of concrete.

However, it is also possible to fill in some components (coarse aggregate) and then fill the holes with a specially prepared cement mortar to fill in all the holes and form a concrete block.

Read Also: Cast in situ or Precast Concrete! Which one is a Better method