Soil compaction is a necessary phase of the construction process. It is used to assist structural entities such as building foundations, roads, sidewalks and earthwork structures. For a given soil type, sure attributes might also be greater or much less appropriate to operate thoroughly in unique situations. Generally, the pre-selected soil needs to have enough strength and be relatively incompressible, so that the future settlement will not be large. When the water content or other different factors change, it is secure to modifications in volume, and should be durable and safe, and has splendid Permeability.

What is Soil Compaction?

Soil compaction has been described as a technique of mechanically increasing density and bearing capacity of soil. Soil stress happens when soil particles are pressed together, decreasing the pore space between them. In construction, it is an important part of the constructing process. If performed incorrectly, the soil can settle and end result in needless renovation expenses or structural failure. Almost all types of constructing sites and building projects use mechanical compression techniques.

Factors affecting the soil compaction

The different factors which affect the compaction of soil are describe in below.

- Water Content

- Type of Soil

- Type of compactor (Equipment)

- Layer thickness

- Amount of Compaction (Roller passes)

- Speed of Rolling

- Contact pressure

Water content

With less water content, the soil hardens and becomes more resistant to compression. As the amount of water increases, the soil particles become lubricated. The quality of the soil becomes easier to handle and the particles fill harder. As the amount of water increases, the dry density of the soil will increase until the maximum amount of water is reached. At this stage, the void reaches an almost constant volume. As the water content increases further, the voids do not decrease, however the total voids will increase and the dry density decreases.

Therefore, by forcing air voids from soil voids, the highest moisture is reached and therefore a higher dry density is obtained. Once the maximum amount of water is reached, minimize the air voids is difficult.

Type of soil

The type of soil greatly affects its compression properties. In general, heavy soils, soils and silt have high compression resistance, while sandy soils and coarse grains or gravel soils are easy to compact. Compared to clay, coarse-grained soils have a higher density. Well graded soil can be compacted with high density.

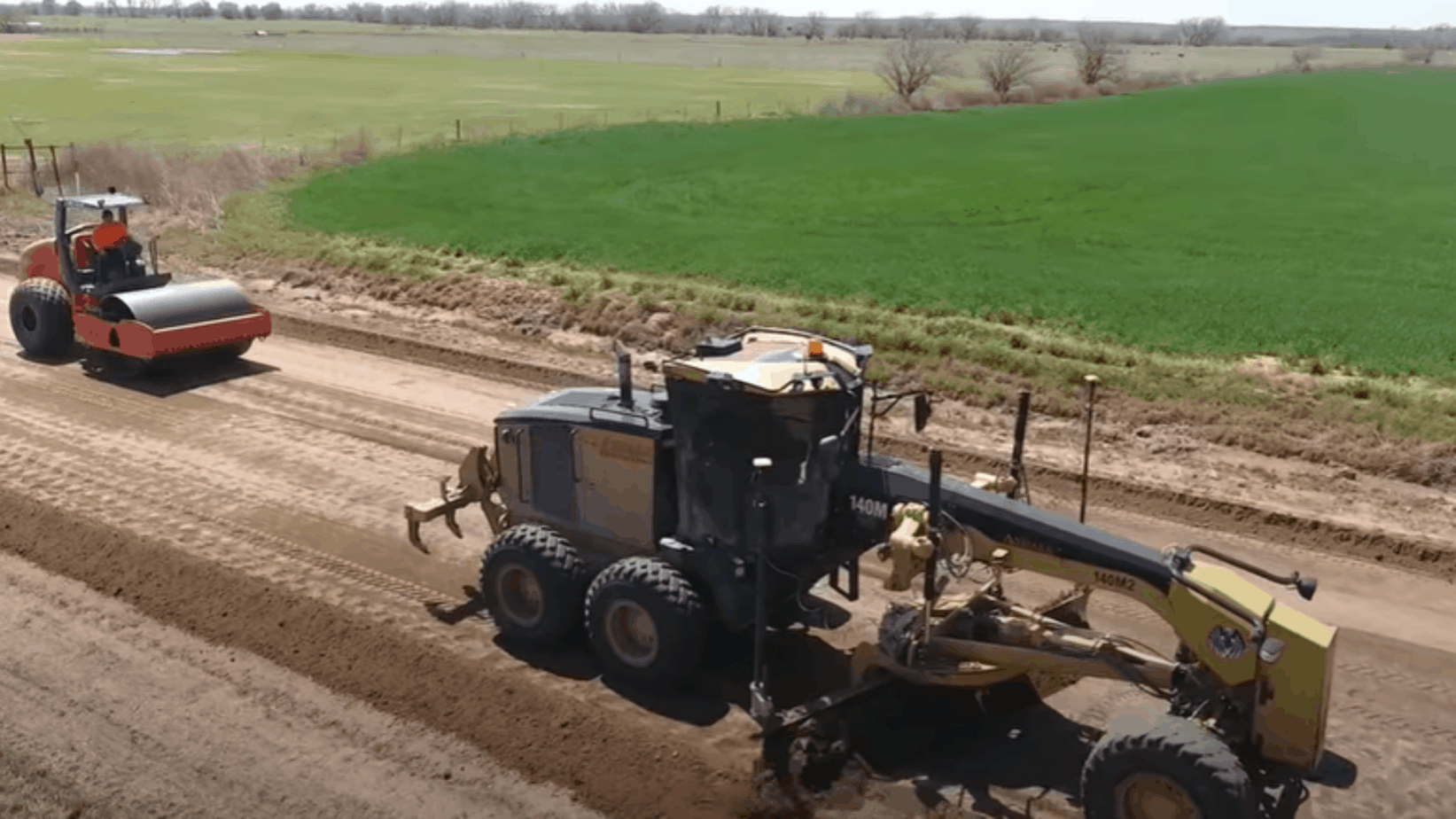

Type of Compactor (Equipment)

The choice of equipment relies upon to a massive extent on the nature and characteristics of the soil to be compacted, as well as the amount of material or soil to be compacted.

Generally, it is best to use pad foot compactors and compactors with high friction to compact cohesive soil, and use smooth rollers and bottoms to compact the non-cohesive clamping compactor more effectively. The use of a number of compactors to dynamically compact the soil has established to be a very effective construction method.

For any construction project, soil compaction is an important and possible process, which requires special attention and the use of quality compaction equipment to gain best results.

Layer Thickness

The degree of compression is inversely proportional to the thickness of the layer, that is, for a given compression energy, a thick layer has less compression than a thin layer. The reason is that for deeper soil layers, less energy input per unit weight. Therefore, it is very important to determine the correct thickness of each layer to achieve the desired density. The thickness of this layer depends on many other factors, such as soil type, material type, and so on. Typically, a layer thickness of 200 to 300 mm is used to achieve uniform compression in this field.

Amount of Compaction (Roller passes)

Soil compaction increases as the amount of compaction effort increases. As compaction efforts increase, the most water content required for compaction also decreases. The greater the amount of water, the increased the effect of increasing compression.

With most water content, the volume of air becomes almost stable and the effect of increased compression on the soil is no longer significant. It may additionally be mentioned that the maximum dry density does not increase with increasing compression effort. With a certain increase in compression effort, the extend in dry, dry density turns into lower. Finally, a stage has been reached beyond which the dry density has not improved further which has increased the compression effort.

Speed of Rolling

Rolling speed is an essential factor in the high pace of the soil. There are two important things to consider. First of all, the faster it speeds up, the more backs it can compact in a day. Secondly, at excessive rolling speeds, it may take a long time to correct, so more passes may be needed to acquire the desired compression.

Therefore, we need to strike a balance between these two things. Generally, the speed limit of all drums is 5 km per hour. The speed of the vibration roller is an important factor, because the variety of vibrations per minute is independent of the forward speed. Therefore, the speed of travel needs to be slower, the vibration at a fixed point more, and the passage less to reach a given density.

Contact pressure

The contact pressure is the pressure between the soil and the wheels of the compactor. The pressure depends on the weight and contact area of the roller. High pressure contact will increase the dry density and reduce the maximum moisture content.

Importance of Soil Compaction

Soil compaction is important because it provides a flat foundation for a variety of construction works. If the soil is not compacted properly, it will cause catastrophe in the future. Over time, the soil may move suddenly and water may flow below the surface of the foundation. This movement can damage the walls of the building and even cause it to collapse. If soil is not properly managed during construction, the road can become unstable and pipes can burst at the bottom.

Compaction provides stability and support to the structure built on top of it. This process increases the elasticity of the soil. The details need to be considered because it is important to ensure the correct support structure. When construction begins, the soil is often destroyed, allowing water and air to enter. The soil compression process removes water and air, thus forming a strong foundation.

Soil competition increases soil strength and decreases its compressibility. Soil permeability is also reduced because when the interval between particles decreases, the flow of water through the soil becomes more difficult. As a result of this process, the soil can withstand more weight and its stability increases. It also improves its ability to prevent frost or deformation damage.