The use of the shear wall types is justified in the case of high-rise buildings because the wind pressure and earthquake forces are higher in such cases. The shear walls have a plane or flanged type of structure. In some cases, the core walls are made up of channel sections, as they provide resistance towards lateral displacements.

In this article, we will discuss types of shear wall, and design techniques for shear walls. Let’s start with the introduction of the shear wall.

What is Shear Wall?

It is a member of the structure used to act against the lateral forces such as the forces which are applied in a parallel direction to the plane. In the case of slender walls, the bending value is more but it resists the load with the help of is cantilever action.

In the construction of buildings, a solid vertical diaphragm which able to transfer the load to the ground acted by floors, walls, roofs. This type of load acts in a parallel direction. The main example of such type of structure is a cantilever reinforced wall. The seismic and settlement in the structure can result in failure of the structure by shear. So in order to cope with that, shear walls are necessary.

Difference Between Shear Wall and Normal Wall

The normal type of wall is non- load bearing wall which is also term3d as the dividing wall. They have less importance in the structure. They are not integrally attached to the foundation of the diaphragm of the reinforced structure. A normal wall mostly serves the purpose of acting as a partition between the rooms.

While the use of a shear wall is to serve the resistance against the shear forces acting on the building. The direction of the wind and horizontal earthquake forces is normally perpendicular to the structure.

There some criteria that needs to be fulfilled in the case of the shear wall which is the attachment of the shear wall to any portion of the structure, mostly the foundation of the structure. The tipping forces are the forces that are used to resist the shear forces acting on the structure.

When it is built in the structure, the forces which previously were acting to affect the whole building will try to lift the corner of the wall. This is the reason why the wall needs to be connected with the foundation of the structure.

Location of Shear Wall

The location of the shear walls depends on the plan of structure, core location, the symmetry of the building, and the lateral force experienced by the structure. Mostly, shear walls should be placed around the outer walls of the building in a symmetrical form. It is usually very difficult to find a suitable location for the shear wall in the structure. However, the ideal place is the center of the building. Sometimes, structural analysis is performed to identify the ideal location in the structure.

What is the Purpose of Shear Wall?

The main purpose of the shear wall in the structure are to provide the lateral strength to the building and to provide lateral stiffness to the building in the direction of their orientation, which decreases the sway of the build in horizontal direction which in turn make the structure same room failure.

Strategies for Design of Shear Walls

There are three kinds of design strategies,

- Segmented shear wall method

- Force transfer method

- Perforated shear wall method

Segmented shear wall method

This method utilizes full tallness shear walls sections that are used to proportion necessities and are typically limited against overturning by hold down materials at the end of each portion.

Force Transfer Method

The force transfer method to design the shear wall considers the whole shear wall with openings and the wall openings around the walls as portions. The technique requires the force around the border of the openings to be analyzed and designed completely.

With this strategy, the hold-down things for the most part happen at the end of the shear wall, not at each pier of the wall, and around the opening special type of reinforcement is required.

Perforated Shear Wall Technique

The third and most up to date strategy is the perforated shear wall technique, which is an exact methodology that doesn’t need special force transfer neighboring the openings.

The punctured shear divider strategy, in any case, explicitly requires hold-down devices at each end of the perforated shear wall. The thickness of the wall is between 150 mm to 400 mm. The breadth of bars is between 1/10 of the divider thickness. The minimum allowed reinforcement is 0.25% of the cross-sectional area.

Different Types of Shear Wall

- RC Shear Walls

- Plywood Shear Walls

- Mid ply Shear Walls

- RC Hollow Concrete Block Masonry Wall

- Steel Plate Shear Walls

RC Shear Wall

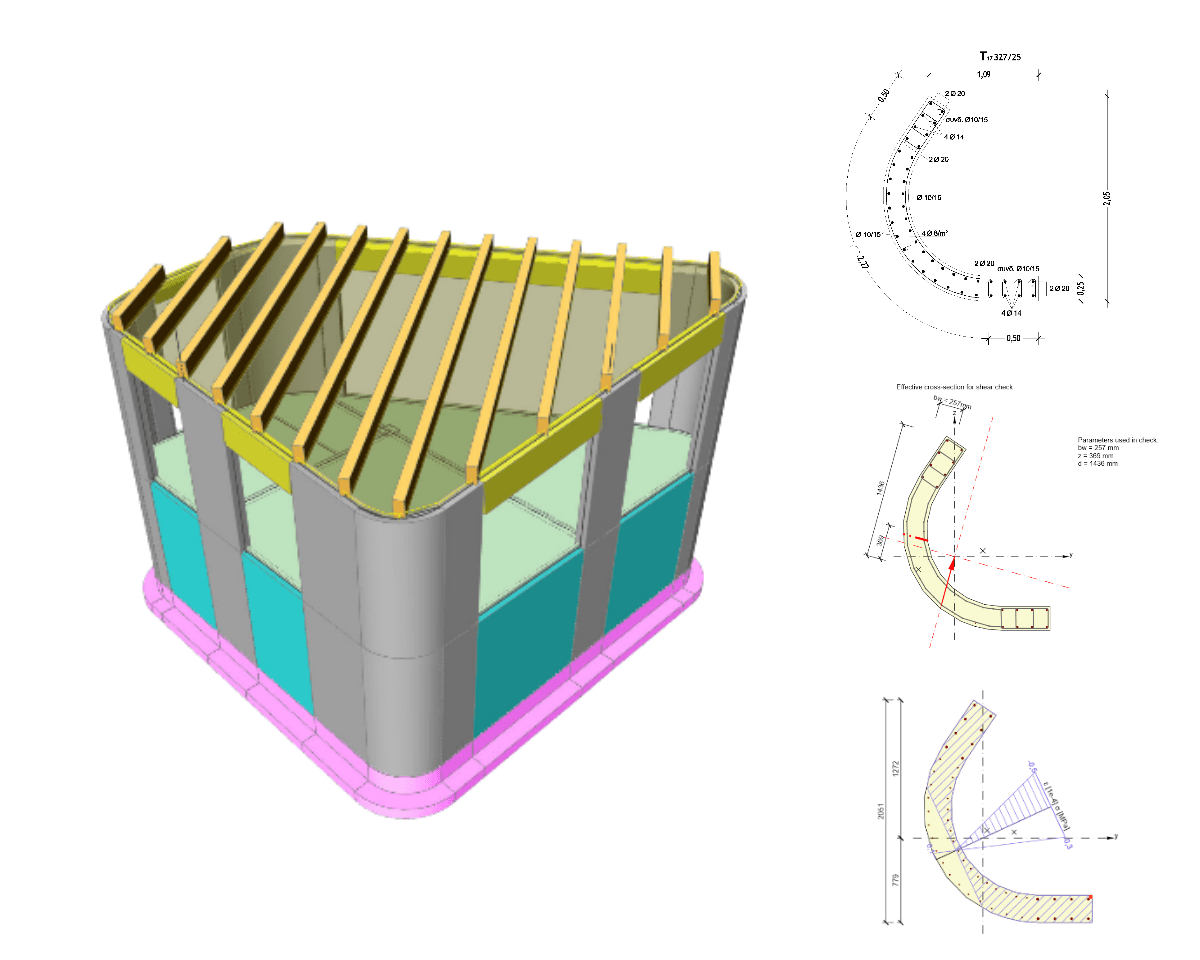

These types of shear wall comprise reinforced walls of concrete and strengthened slabs of concrete. Wall thickness fluctuates from 140 mm to 500 mm, contingent upon the number of stories, building age, and thermal insulation necessities.

Moreover, these types of shear wall are persistent all through the structure height. There are rare cases when shear walls are discontinued at the road front or basement level to provide space for commercial or parking spots. Normally the wall design is symmetrical with one of its axis of symmetry.

Mostly, the wall reinforcement comprises of two layers of reinforcement distributed in the horizontal and vertical direction, all through the wall length. Also, reinforcement in vertical direction bars is given near the door and window openings, just as at the end zones of walls.

Ply wood Shear Wall

Plywood is the conventional material utilized in the development of Shear Walls. The making of pre-assembled shear boards have made it conceivable to infuse solid shear gatherings into little dividers that fall at either side of an opening in a shear walls.

As well as the utilization of sheet steel, and packed steel shear walls, has ended up being far stronger in resistance to seismic forces when utilized in shear walls. Plywood, to move shear forces, Chords, to oppose strain/pressure produced by the overturning moments. Base connections that perform the transfer of forces to the foundation.

Mid ply shear walls

These types of shear wall are an improved wood shear wall that was created by upgrading the joints among sheathing and members in framing, so the failures observed in standard testing, are practically removed at the level of lateral load, which are large enough to cause failure in the standard wall.

In mid ply shear divider plan, one ply of sheathing material is set at the center of the wall between a series of sets of studs arranged in a 90° turned position comparative with those in standard shear walls.

RC hollow concrete block masonry walls

Reinforced hollow concrete block masonry walls are developed by the provision of reinforcement in the hollow concrete block masonry, by utilizing hollow spaces and their shapes. This type of shear wall requires reinforcement of steel in horizontal and vertical directions at critical locations of the structure, filled with the new grout concrete in the empty spaces of masonry blocks.

Reinforced Hollow Concrete Block Masonry (RHCBM) components are planned both as load-bearing walls for gravity loads and furthermore as shear walls for lateral seismic effect, to bear the effect of earthquake forces.. this type of construction is termed as shear wall- diaphragm concept, which gives three-dimensional stiffness to the buildings.

Steel plate shear wall

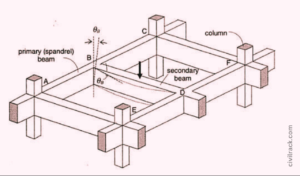

In general, these types of shear walls system consists of a steel plate wall, boundary columns, and horizontal floor beams together, the steel plate wall and boundary columns act as a vertical plate girder. The columns act as flanges of the vertical plate girder and the steel plate wall acts as its web. The horizontal floor beams act, more-or-less, as transverse stiffeners in a plate girder.

Thickness of Shear Wall

According to the ACI code in 1963, the thickness adopted depended on the working stress design. The minimum thickness adopted was 6 inches for walls in 2 storey. This thickness will be increased by 1-inch thickness for every 25 ft below the top 2 storey. Wall thickness varies from 140 mm to 500 mm. Wall thickness depends on the number of stories, building age, and thermal insulation requirements.

Key Points for Shear Walls

- In structures, a shear wall is a vertical component of a seismic force opposing framework. It is intended to oppose in-plane forces in the lateral direction, ordinarily, wind, and seismic loads.

- Most RC structures with shear walls additionally have columns; which carry gravity loads (i.e., those because of self-weight of the building). Shear walls give stiffness and strength to the structure in their orientation, which fundamentally decreases the horizontal influence of the structure and which prevents the failure of the structure.

- It resists horizontal earthquake forces, so the moments are large which affects the shear walls. Subsequently, the design of their foundation requires special consideration.

- It ought to be given along ideally both length and width. Be that as it may, in the event that they are given along just a single bearing, a proper pattern of beams and columns sections in the vertical plane must be given along the other direction to oppose high earthquake impacts.

- Doors or window openings can be given in shear walls. Their size must be little to guarantee the least interference to the flow of force from walls. Additionally, openings should be symmetrically located. Special checks are needed to guarantee that the net cross-sectional area of the wall at an opening is strong enough to carry the seismic loads.

Advantages of Shear Walls

Some advantages of shear wall are:

- The shear wall provides greater strength and rigidity to building in the orientation direction.

- It reduces the horizontal moment of building.

- This wall is easy to build.

- It is effective in terms of construction costs.

- These walls provide stability to structure against seismic loads and effective in reducing earthquake damage.

- By using this type of wall, structure weight can be reduced due to these are thin and lightweight.

- In these walls, the steel bars are evenly distributed.

- These are proficient, both as far as development cost and viability in resisting earthquakes in structural and nonstructural components.