Concrete is everywhere—from the sidewalks we walk on to the towering buildings that shape our cities. But have you ever wondered what makes concrete so strong and durable? The secret lies in two important processes: hydration and curing. In this guide, we’ll break down these concepts in simple terms, explain why they are important, and show how modern innovations are helping create even better concrete structures—all while focusing on the principles of Concrete Curing and hydration.

Introduction

Imagine pouring cake batter into a pan without ever baking it. No matter how good the ingredients are, the cake will never come out right. In a similar way, fresh concrete needs proper “baking” through curing to reach its full strength.

Why It Matters

Concrete isn’t just a mix of cement, water, and rocks; it transforms into a rock-solid material thanks to a chemical reaction known as hydration. Curing is the process of keeping concrete moist and at the right temperature so that this hydration reaction happens completely. Without proper curing, concrete can be weak, crack easily, and shorten the lifespan of structures like bridges, roads, and buildings.

What We’ll Cover:

We’ll start with the basics of hydration and curing, discuss what concrete is made of, look at the different stages of curing, and then explore what factors affect the process. Finally, we’ll highlight best practices and innovative techniques that are making concrete even better. Understanding these steps is essential for mastering Concrete Curing and hydration in any construction project.

Understanding Concrete Curing and Hydration

What Is Hydration?

When you mix cement with water, a chemical reaction called hydration begins. Think of hydration as the “magic” that turns a liquid mix into a solid material. Here’s a simple breakdown:

- Hydration Explained:

When water meets cement, it triggers a reaction that forms tiny crystals. These crystals grow and stick together, eventually forming a gel that binds the mixture into a solid mass. The most important product of this reaction is called C-S-H (calcium-silicate-hydrate), which gives concrete its strength.

What Is Curing?

Curing is all about giving the concrete the right conditions to let hydration happen fully. This means keeping the concrete moist and at an ideal temperature for a set period. Without curing, the concrete might dry too quickly, stopping the hydration process before the structure reaches its full strength.

Example:

Imagine making bread. After preparing the dough, it needs time to rise in a warm, humid environment. If the dough dries out or is kept in a cold room, the bread won’t turn out as soft or fluffy. Curing concrete works in a similar way—it’s the step that ensures your concrete can develop into a strong, lasting structure.

Why Are Hydration and Curing So Important?

- Strength and Durability:

A fully hydrated and properly cured concrete mix becomes much stronger and lasts longer. It is less likely to crack or break under pressure. - Avoiding Structural Weakness:

Poor curing can leave parts of the concrete under-hydrated, which leads to weak spots. This is why focusing on Concrete Curing and hydration is essential to prevent future damage.

What’s Inside Concrete? (Chemical Composition)

Concrete might seem simple, but it’s a carefully balanced mix of several ingredients. Here’s what goes into it:

The Main Ingredients

- Cement:

The key binding agent. Most concrete uses a type called Portland cement. There are different types (labeled I to V) used depending on the project requirements. - Water:

Not only does water mix the ingredients together, but it also starts the hydration reaction. - Aggregates:

These are the rocks, gravel, or sand added to give concrete bulk and strength. - Admixtures:

Chemicals added to modify the mix’s properties. For instance, accelerators (like calcium chloride) help the concrete set faster, while retarders (like gypsum) slow down the setting process when needed.

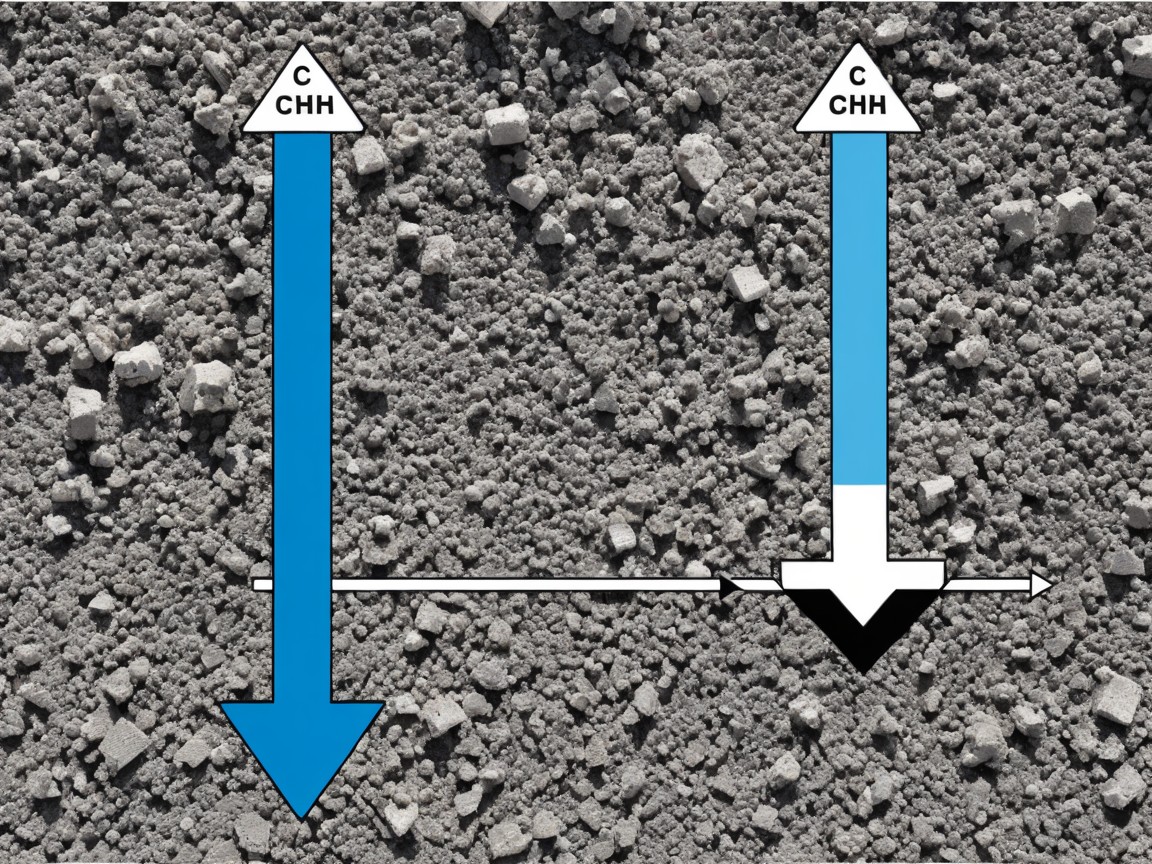

How Hydration Works at a Chemical Level

When water is added to cement, it reacts with compounds found in the cement (often named C3S, C2S, C3A, and C4AF). Here’s a simple look at what happens:

- Step 1: Dissolution:

Water breaks down some of the cement particles into tiny ions. - Step 2: Gel Formation:

These ions form a gel-like substance that begins to bind the ingredients. - Step 3: Hardening:

As more gel forms and interlocks with the aggregates, the concrete hardens into a solid mass.

Heat Generation:

This chemical reaction releases heat, which can help in cold weather but may cause cracking if too much heat builds up. Monitoring and controlling temperature during curing is a key aspect of Concrete Curing and hydration.

The Stages of Concrete Curing

Knowing the timeline of concrete curing helps ensure that each step is handled correctly.

Stage 1: Initial Set (0–24 Hours)

- What Happens:

During the first day, the surface of the concrete starts to harden. - Practical Tip:

Avoid walking on or disturbing the concrete during this fragile period.

Stage 2: Final Set (24–48 Hours)

- What Happens:

The concrete continues to harden gradually, though it is still in a transition phase. - Practical Tip:

Keep the environment stable by maintaining consistent moisture and temperature.

Stage 3: Strength Gain

- 7-Day Mark:

After about a week, concrete typically reaches around 70% of its full strength—an important milestone for construction. - 28-Day Mark:

Concrete is usually considered to have nearly reached its maximum strength after 28 days. This is why strength tests are often performed at this point. - Long-Term Strength:

Even after 28 days, the hydration reaction continues slowly, making the concrete even stronger over the years.

Factors That Affect Hydration and Curing

Several factors can influence how well concrete cures and gains strength. Let’s look at these factors in straightforward language:

Temperature

- High Temperature:

Accelerates the hydration process, but may cause rapid drying and cracks if not controlled. - Low Temperature:

Slows down the reaction, delaying strength gain. In cold conditions, extra measures like heaters or insulation might be necessary.

Humidity

- Moisture is Key:

Keeping the concrete moist is essential for a complete hydration reaction. If it dries out too soon, it won’t reach its full potential. - Practical Example:

On a dry, sunny day, covering concrete with wet burlap or plastic can help keep the moisture in.

Water-Cement Ratio

- Balance is Critical:

A lower water-to-cement ratio generally means stronger concrete because there’s less extra water that can create weak spots. However, too little water can make the mix hard to work with. - Practical Example:

Just like cooking, adding the right amount of liquid is crucial for the perfect recipe.

Admixtures

- Adjusting the Mix:

Admixtures help control how quickly concrete sets. Accelerators are useful in cooler weather to speed up the process, while retarders give extra time during hot weather.

Read More: Admixtures In Concrete – Different Types And Functions

Cement Type

- Choosing the Right Cement:

Some cements are designed to set quickly (fast-setting) for early strength, while others are formulated to produce less heat (low-heat) for large structures where temperature control is crucial.

Best Practices for Effective Curing

To ensure that concrete reaches its maximum strength, it’s important to follow proven curing methods. Here are some easy-to-understand techniques with practical examples:

Water Curing

- How It Works:

The simplest method is to keep the concrete surface moist. This can be done by creating a shallow pool of water (ponding), using sprinklers, or even immersing the concrete. - Practical Example:

Think of it like keeping a sponge wet so it can properly absorb water.

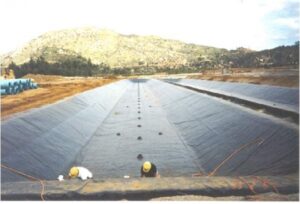

Membrane-Forming Compounds

- How It Works:

These special liquids are sprayed or rolled onto the concrete surface, forming a protective layer that traps moisture inside. - Practical Example:

It’s like wearing a raincoat to protect yourself from the elements.

Steam Curing

- How It Works:

Often used in factories making precast concrete elements, steam curing exposes the concrete to steam. This speeds up the hydration process. - Practical Example:

Imagine using a steamer to cook vegetables faster and more evenly.

Covering with Wet Burlap or Plastic Sheeting

- How It Works:

Laying down wet burlap or plastic over the concrete helps retain moisture. - Practical Example:

It’s similar to covering a dish with a lid to keep heat and moisture in while cooking.

How Long Should Concrete Be Cured?

- Minimum Time:

Most standard concrete mixes need at least 7 days of curing. In cold or very dry weather, a longer curing period is recommended. - Practical Example:

Like letting bread dough rise longer on a chilly day, concrete sometimes needs extra time to develop its full strength.

Common Mistakes to Avoid

- Drying Out Too Soon:

If the concrete dries before the hydration reaction is complete, its final strength will be lower. - Unstable Temperature:

Sudden temperature changes can lead to uneven curing and cracks. - Poor Moisture Control:

Inconsistent moisture levels can prevent full hydration and reduce durability.

Looking to the Future: Innovations in Curing

The world of concrete is not standing still. New technologies and practices are helping us build even stronger and more sustainable structures. Here are a few exciting innovations:

Eco-Friendly Admixtures

- What’s New:

New, environmentally friendly admixtures are being developed that support proper curing while reducing the overall carbon footprint. - How It Helps:

These admixtures improve the hydration process, making concrete both stronger and more sustainable. - Practical Example:

Think of it as choosing organic ingredients for a healthier recipe—better for you and the planet.

Conclusion

Concrete is one of the most important materials in modern construction, and its strength and durability depend on the careful process of hydration and curing. Just like baking a cake or letting bread dough rise, concrete needs the right conditions—moisture, temperature, and time—to become strong and long-lasting.

Key Takeaways:

- Hydration:

The chemical reaction between water and cement transforms a liquid mix into a solid, durable material. - Curing:

The process of maintaining the right conditions for hydration to occur fully. - Stages:

From the initial set (0–24 hours) to the final set (24–48 hours) and beyond, each phase is critical. - Factors:

Temperature, humidity, water-cement ratio, and admixtures all affect how well concrete cures. - Innovations:

Modern techniques such as AI-driven curing systems, eco-friendly admixtures, and advanced sensors are making concrete even better.

By understanding and applying the principles of Concrete Curing and hydration, we can build structures that stand the test of time. Whether you’re an engineer, contractor, or simply curious about how our built environment comes together, knowing the basics of hydration and curing can help you appreciate the hidden science behind every sturdy road, bridge, and building.