Spandrel beams play a crucial role in structures. They provide both structural support and aesthetic appeal to buildings. However, what exactly is a spandrel beam? How does it differ from other types of beams?

In this article, we will explain everything you need to know about spandrel beams. We will cover their functions, types, uses, and how they fit into the overall structure of a building.

What Is Spandrel Beam?

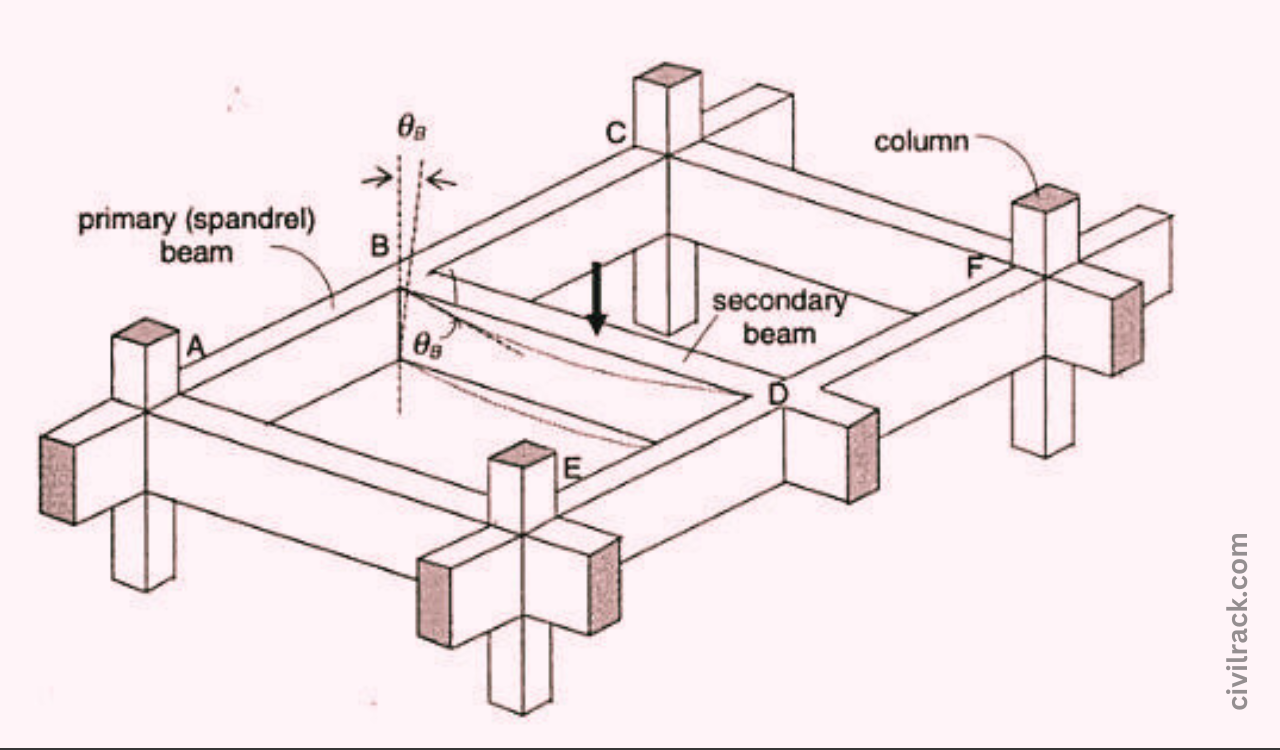

A spandrel beam is a horizontal beam that runs between two vertical columns in a building. These beams often support the weight of floors or roof sections. They also help create smooth transitions between different sections of a structure.

Spandrel beams differ from other types of beams like lintels or girders. A lintel supports the structure above doors and windows. A girder, on the other hand, is a main horizontal support that spans larger areas. Spandrel beams focus on connecting columns and supporting walls, floors, or facade systems.

Key Functions of Spandrel Beams

Spandrel beams serve several essential functions in construction:

- Structural Support: They provide the necessary support between floors or sections of a building. This ensures that the weight of the structure gets distributed properly across different points.

- Load Distribution: Beams help spread the weight of walls and floors evenly. They carry this weight from one section of a building to another without adding stress to specific areas.

- Facades and Curtain Walls: Beams are crucial for curtain wall systems, especially in high-rise buildings. These beams help support the glass panels or facade sections between floors.

- Connections between Columns: These beams connect the vertical columns in a building, creating a stable framework that holds the entire structure together.

Types of Spandrel Beams

There are several types of spandrel beams used in construction, depending on the material and purpose:

- Concrete Spandrel Beams: These are the most common type of spandrel beams. Builders use concrete beams in multi-story buildings. They offer strength and durability, making them suitable for high-rise structures.

- Steel Spandrel Beams: Steel beams are lighter and often used in modern or minimalist structures. They are easier to install and provide more flexibility in design. Steel is also less bulky, making it ideal for buildings with sleek architectural designs.

- Precast Spandrel Beams: These are made off-site in a factory and transported to the construction site. Precast beams allow for faster construction since they arrive ready for installation. Builders prefer them for projects with tight deadlines.

Each type has its own benefits, and the choice depends on the specific needs of the building.

Applications in Construction

Spandrel beams are used in various types of buildings and structures. Some common applications include:

- High-Rise Buildings and Skyscrapers: Spandrel beams play an important role in supporting the floors between each level. They help distribute the building’s weight evenly across the columns and walls.

- Commercial Complexes and Office Buildings: In office buildings, spandrel beams support curtain walls and glass facades, giving the structure a sleek, attractive look while providing strong support.

- Parking Garages and Bridges: In these structures, beams help carry the weight of heavy vehicles. They also provide stability and structural strength to the overall framework.

- Curtain Wall Systems: Beams are essential in supporting curtain wall systems, which consist of large glass panels or cladding. These beams carry the weight of the facade while ensuring that it aligns perfectly with the rest of the building.

Spandrel beams play both structural and aesthetic roles. This makes them valuable for large, complex buildings that require both strength and style.

Design Considerations for Spandrel Beams

Several factors go into the design of spandrel beams:

- Load-Bearing Capacity: The beam must be strong enough to handle the weight of the structure above it. Engineers calculate the expected load and choose materials and sizes accordingly.

- Material Selection: Choosing between concrete, steel, or precast depends on the project’s needs. Concrete offers strength, steel provides flexibility, and precast beams speed up construction.

- Fire Resistance and Durability: Spandrel beams should be designed to withstand potential fire hazards. Concrete beams are naturally fire-resistant, while steel beams need protective coatings to prevent heat damage.

- Main Reinforcement: The main reinforcement used in the beam should not be less than 12 mm in diameter. This ensures adequate strength to support the load.

- Stirrup Spacing: The spacing between the stirrups (the reinforcement bars placed in a beam to resist shear stress) should not be less than 250 mm. Proper stirrup placement helps prevent bending or cracking under load.

- Crank Bars: Crank bars should be used if possible. These are bent reinforcement bars that improve the beam’s resistance to tension and prevent sagging.

- Beam Thickness: The minimum thickness of a spandrel beam should not be less than 5 inches. The maximum thickness depends on the load-bearing requirements. This ensures that the beam can handle the weight placed upon it without buckling or cracking.

- Proper Connection with Columns: The reinforcement of the column and spandrel beam must be connected properly. This connection is crucial to ensure that the beam can bear the load of the masonry structure above it without cracking or failing.

- Clear Cover: The minimum clear cover (the space between the outer surface of the beam and the reinforcement bars inside) should not be less than 16 mm. This cover protects the reinforcement from corrosion and other environmental damage.

- Avoid Lapping of Steel Rods at Mid-Span: Lapping (the overlapping of steel reinforcement rods) should be avoided at the mid-span of the beam as much as possible. Mid-span is where the beam experiences the most tension, and lapping in this area could weaken its structural integrity.

- Integration with Other Elements: Spandrel beams must align properly with other parts of the building, such as columns, slabs, and walls. This ensures that the building remains stable and balanced.

Proper design and attention to these factors ensure that the spandrel beam can handle the expected stresses and loads without compromising the building’s safety.

Construction Methods for Spandrel Beams

There are two main methods for constructing spandrel beams:

- Precast Beams: These are manufactured in a factory and transported to the site. Precast beams speed up the construction process since they arrive ready for installation. Builders prefer this method for large projects that need to be completed quickly. Precast beams also ensure consistent quality, as they are produced under controlled conditions.

- Cast-In-Place Beams: In this method, workers build the beams directly on the construction site using molds and concrete. Cast-in-place beams offer more customization, as they can be adjusted on-site to fit the exact dimensions and requirements. This method is ideal for projects where flexibility is important.

Installation: Once the beams are ready, workers lift them into place and secure them to the columns. They also reinforce the connections with additional steel or concrete to ensure stability.

Both methods have their advantages. Precast beams save time, while cast-in-place beams allow for more design flexibility.

Advantages of Using Spandrel Beams

Spandrel beams offer many benefits in construction:

- Structural Stability: They provide strong connections between columns and floors, making buildings safer and more stable.

- Aesthetic Appeal: These beams support curtain walls and facades, giving buildings a attractive, clean look. Architects often use them to enhance the overall appearance of the structure.

- Design Flexibility: Spandrel beams can be adjusted to fit various architectural designs. They can support large glass panels, concrete walls, or other cladding materials.

- Load-Bearing Capacity: Spandrel beams handle heavy loads, making them ideal for multi-story buildings and complex structures.

These advantages make spandrel beams a popular choice in structures.

Limitations and Challenges

Despite their many benefits, spandrel beams also come with some challenges:

- High Costs: Spandrel beams, especially precast ones, can be expensive to manufacture and install. The cost of materials, labor, and transportation adds to the overall budget.

- Complex Design and Installation: Designing of beams requires careful planning to ensure proper load distribution. Installing them can also be complicated, especially in large projects.

- Maintenance Concerns: Over time, weather and environmental factors can affect the durability of exposed beams. Steel beams may corrode, and concrete beams may crack, requiring regular inspections and maintenance.

Builders must weigh these challenges against the benefits when deciding whether to use beams in a project.

Conclusion

Spandrel beams play an essential role in any structure. They provide structural stability, support for facades, and help distribute the weight of floors and walls. Whether using concrete, steel, or precast beams, builders rely on these beams to ensure the safety and appearance of their buildings.

Although they come with challenges, such as high costs and maintenance needs, spandrel beams remain a crucial part of many construction projects. With new innovations and materials, the future of these beams looks promising, especially as the industry continues to focus on sustainability and energy efficiency.

Understanding spandrel beams can help architects, builders, and homeowners appreciate their value in creating safe and beautiful structures.