The bearing capacity of soil plays a very important role to choose the type of foundation for the structure. To transfer a load of the structure to soil with low bearing capacity, a grillage foundation can be helpful.

As the grillage foundation improves the hydrodynamic performance during installation, the grid foundation can be selected instead of the standard shallow sea foundation. They consist of vertical grids that penetrate the seafloor. During vertical loading, if sufficient penetration is allowed, the bearing capacity of a conventional surface foundation can be obtained from the grid foundation.

What is Grillage Foundation?

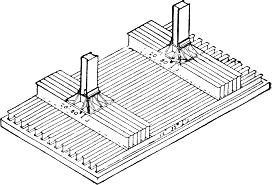

The grillage foundation consists of multiple layers of beams, which are usually placed at right angles to each other to distribute the heavy load from the superstructure to an acceptable soil bearing capacity.

Today, except for very heavy loads, grid foundations are rarely economical for permanent foundations. However, their prefabricated form is very useful for temporary work, especially when the foundation needs to be reused. Foundations that install offshore infrastructure on the seafloor are very popular.

Unlike piles, this type of foundation was found to be a lighter and most economical solution. It does not require deep excavation, but it can still provide the necessary area for soil bearing capacity. Piles, caissons, and piers require deep excavation, which is a big disadvantage in the case of site constraints.

Suitability of Grillage foundation

- This type of grillage foundation is suitable for building structures with lightweight construction materials on weak soil.

- Based on the foundation, the foundation hopes to save up to 30% of the cost.

- Where it is not allowed to construct other types of foundations in areas with weak soil properties and occurrence conditions.

- For the grillage foundation, the load of the structure should be expected to be relatively small.

The function of the Grillage foundation

The grillage beams connect the entire foundation to a single structure, thus helping to evenly distribute the weight of the house and all piles.

In most cases, this foundation is organized as a whole reinforced concrete structure. Resistance is provided by the metal structure.

Types of Grillage Foundation

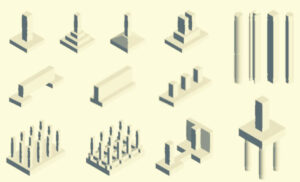

There are three types of grillage foundations as per the use of material.

- Steel grillage

- Timber grillage

- Concrete grillage

Steel Grillage Foundation

The steel grillage foundation consists of joints or steel beams provided by single or double layers. Its name defines its function and structure because it is composed of steel beams, structurally called rolled steel beams.

Keep at least 10 cm coverage on the outside of the outer beam and above the upper flange of the upper layer.

The depth of the concrete must be at least 15 cm. After leveling the foundation and pouring the concrete, we must check whether the compaction is correct and form an impermeable layer with a thickness of not less than 15 cm.

It can protect steel beams from groundwater pollution, which would otherwise cause corrosion. Then, with the help of a pipe separator, the first layer of beams misplaced on a concrete bed at a distance of 100 to 300 mm.

Then, we poured concrete between and around the beams on the first floor. After that, with the help of a splitter, the second beam horizontal line is at right angles to the first beam horizontal line.

Again, we pour concrete between and around the steel beams. To this end, we connect the steel brackets to the top layer with the help of the bottom plate, side corners, and reinforcing plates.

These connecting elements are also buried in concrete to make the joints strong.

Timber Grillage Foundation

Provides a wooden structure foundation for the heavy-duty masonry wall of wooden columns. The foundation is especially suitable for flooded areas, where the bearing capacity of the soil is very low, and the soil load is limited to 50-60 KN/m2.

Instead of steel joists, planks and beams were used. There is no concrete surround between the timber joints.

However, the bottom concrete provided in the steel grating is replaced by a timber platform constructed of planks. Excavation level of the foundation. Place the bottom layer of wooden boards with a size of 20-30cm and a width of 5-7.5cm side by side, without any gaps between them.

At the top of this layer, wooden beams with the same cross-section as the piles are placed at right angles. Then place another layer of wood at right angles to the beam direction again. The upper layer of the plank may be 7.5-10 cm. Thick, extending over the entire width of the base of the masonry wall.

Concrete Grillage Foundation

The grille can be made of prefabricated precast concrete components, or it can be made in the form of a monolithic belt.

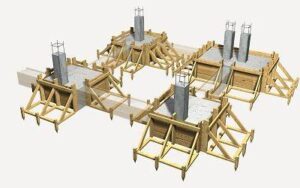

Monolithic Reinforced Concrete Grillage Footing

To produce monolithic reinforced concrete grillage, formwork must first be produced and installed. It can be made of an edge plate in the form of a rectangular slot and must be set so that the gap between the lower part of the future grid and the ground is about 6-8 inches.

Inside the casing, tie wires should be used to set up a frame to strengthen the connection. Such a frame can be constructed as one or two rows of valves connected by crossed rods, or as a laying net in which the two rows are connected by specially curved clamps.

The smaller number of accessories must be placed on a base height of approximately 25-3o mm so that they can be completely immersed in the concrete when pouring. The minimum distance from the frame to the sidewall of the formwork should be the same.

Pouring of pile caps. The steel bars are connected to the same binding line and the steel bars are released. Use a cement mixer to prepare the required amount of concrete and pour it into the formwork in continuous cycles.

In the process of pouring concrete, you must pay attention to its close packing to avoid unfilled cavities. To shrink the concrete better, a vibrator or a traditional bayonet shovel can be used.

After the grid is filled, level the foundation surface and place it until the concrete is completely dry. If the weather is very hot and sunny, the surface of the grille should be moistened regularly. After the concrete is dry, the formwork can be removed.

Precast Concrete Grillage Footing

A prefabricated grillage foundation is provided to support structure, the prefabricated grillage foundation includes: a plurality of anchoring elements that define a grid for resting on a surface below; and a base connected to the grid On the grid, the base includes at least a first base and a second base that are spaced apart, and a connection between and connected to at least the first base and the second base. At least one connecting member.

How to Design a Grillage Footing

For the design of the grillage foundation, it is necessary to calculate the load and moment of the structure. Therefore, we must determine the appropriate foundation area required to allow the ground to bear pressure under the conditions.

Dividing the area, we will find out the number and size of each grillage layer. Then, we must design the layer so that it hangs from the edge of the layer above. It will determine the beam size required to resist bending moments and shear forces.

It is not possible to surround the grid with concrete and sequence, because this will reduce the composite effect of the beam and concrete. Construction and loading methods should be compatible with design necessities.

The capacity of Grillage Footing Under Horizontal Load

As per research (at researchgate.net) Based on the small-scale model test, the behavior of the grillage foundation under the constant horizontal load and constant vertical load in the sand, and the existing plastic-based model for predicting bearing capacity and deformation has been applied and developed. The model has been verified by the model test database.

Compared with equivalent solid surface mud pads with the same vertical load-bearing capacity, the grid foundation in loose and medium-density sand has a higher load-bearing capacity under V-H (in-service) loads.

In medium-density and dense sand, the horizontal ability is good, while in loose sand, it is slightly underestimated. In all test cases, it has been proved that under V-H load, the grille can replace the solid mud pad.

If the prototype grillage is installed under its own weight and the weight of the supporting structure (normal penetration), despite the significant displacement of the foundation (horizontal and vertical) under the initial horizontal load, the initial penetration during installation will be small.

Conversely, if the foundation is excessively penetrated to the initial penetration, it will be greater, but negligible additional penetration can be used to mobilize significant horizontal yield capacity.

In both cases, the lateral foundation response will be strain hardening due to increased vertical penetration. Under large displacements, these two foundations will eventually show similar bearing capacity and total penetration.

Although, under normal penetration, most of the penetration will occur in use, while under excessive penetration, large Partial penetration will occur during installation.

Vertical Capacity of Grillage Foundation in Sand

If sufficient foundation penetration is allowed, an equivalent flat foundation capacity can be obtained. The necessary displacement increases with the increase in pitch ratio, grid thickness, number of foundation grillages, and soil density.

Reference: researchgate.net

Installation Procedure of Grillage Footing

These steps are involved in the construction of grillage foundation,

- For solid monolithic grilles, we must produce and install frames. We prefer this grille because it is more reliable.

- The formwork is made of an edge plate in the form of a rectangular slot. It has a height of 1 foot and a width equal to the minimum wall thickness of the house. The gap between each grid must be set to 6-8 inches.

- Inside the formwork, we have to use tie wires to set up the frame of the steel connection. The minimum distance from the frame to the side of the template is the same.

- Connect the rebar with the same strapping wire used before.

- A cement mixer must be used to prepare the concrete. It is poured into the template in a continuous cycle. The accessories must be placed at a height of approximately 25-30mm so that they are completely immersed in the concrete. The concrete should be poured carefully to avoid unnecessary cavities.

- After filling the surface, the surface must be smoothed and dried. After drying, the template can be removed. The foundation is ready.

Advantages of Grillage Footing

- Less time and materials required for installation;

- Since it is not applied to frozen soil, it can reduce the heat dissipation of the house with the help of the foundation.

- It reduces the vibration level of the house (this is very true if the house is built close to the road

Disadvantages of Grillage Footing

- It needs to build piles at a sufficient depth.

- The space under the grid must be filled and heated.